CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

What are the development trends in the capacitor parallel connection industry?

Development Trends in the Capacitor Parallel Connection Industry

I. Introduction

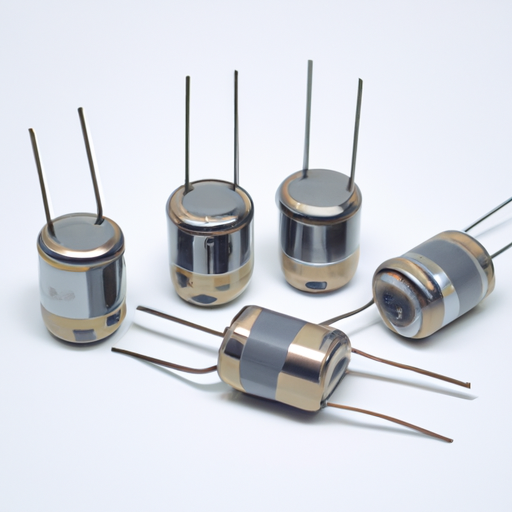

Capacitors are essential components in electrical systems, serving as energy storage devices that can release energy quickly when needed. A capacitor parallel connection involves linking multiple capacitors together to enhance their overall performance, such as increasing capacitance, improving voltage handling, and ensuring reliability in various applications. As the demand for efficient and high-performance electrical systems grows, the capacitor industry is witnessing significant developments. This blog post explores the historical context, current market landscape, and emerging trends shaping the capacitor parallel connection industry.

II. Historical Context

A. Evolution of Capacitor Technology

The journey of capacitor technology began in the 18th century with the invention of the Leyden jar, one of the first capacitors. Over the years, advancements in materials and manufacturing processes have led to the development of various capacitor types, including ceramic, electrolytic, and film capacitors. Each type has unique characteristics that make it suitable for specific applications.

B. Early Applications of Capacitor Parallel Connections

Initially, capacitor parallel connections were primarily used in power supply circuits to stabilize voltage and improve performance. As technology advanced, these connections found applications in audio equipment, radio transmission, and later in more complex systems like computers and telecommunications.

C. Key Milestones in the Industry

The capacitor industry has seen several key milestones, including the introduction of tantalum capacitors in the 1950s, which offered higher capacitance in smaller packages. The 1980s and 1990s marked the rise of surface-mount technology (SMT), allowing for more compact designs and improved performance in consumer electronics.

III. Current Market Landscape

A. Overview of the Capacitor Market

1. Market Size and Growth Rate

The global capacitor market has experienced steady growth, driven by the increasing demand for electronic devices and renewable energy systems. According to recent market research, the capacitor market is projected to reach USD 30 billion by 2025, growing at a CAGR of approximately 5% from 2020 to 2025.

2. Key Players and Manufacturers

The capacitor market is characterized by the presence of several key players, including Murata Manufacturing, Vishay Intertechnology, KEMET Corporation, and Nichicon Corporation. These companies are continuously innovating to meet the evolving needs of various industries.

B. Types of Capacitors Commonly Used in Parallel Connections

1. Ceramic Capacitors

Ceramic capacitors are widely used in parallel connections due to their stability, low cost, and small size. They are commonly found in applications ranging from consumer electronics to automotive systems.

2. Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance values and are often used in power supply circuits. Their ability to handle large amounts of energy makes them ideal for parallel connections in applications requiring significant power.

3. Film Capacitors

Film capacitors offer excellent performance characteristics, including low loss and high reliability. They are increasingly used in parallel connections for applications in renewable energy systems and high-frequency circuits.

C. Applications of Capacitor Parallel Connections

1. Power Electronics

Capacitor parallel connections play a crucial role in power electronics, where they help stabilize voltage and improve efficiency in converters and inverters.

2. Renewable Energy Systems

As the world shifts towards renewable energy, capacitor parallel connections are essential in solar inverters and wind turbine systems, where they help manage energy storage and distribution.

3. Consumer Electronics

In consumer electronics, capacitor parallel connections enhance the performance of devices such as smartphones, laptops, and audio equipment, ensuring stable operation and improved sound quality.

IV. Development Trends in the Capacitor Parallel Connection Industry

A. Technological Advancements

1. Miniaturization of Capacitors

One of the most significant trends in the capacitor industry is the miniaturization of capacitors. As electronic devices become smaller and more compact, the demand for smaller capacitors that can deliver high performance has increased. Manufacturers are investing in advanced materials and manufacturing techniques to produce miniaturized capacitors without compromising performance.

2. Enhanced Performance Characteristics

The performance characteristics of capacitors are continually improving, with advancements in dielectric materials and construction techniques. These enhancements lead to capacitors with higher capacitance values, lower equivalent series resistance (ESR), and improved thermal stability, making them suitable for high-performance applications.

3. Smart Capacitors and IoT Integration

The integration of smart technology into capacitors is another emerging trend. Smart capacitors equipped with sensors and communication capabilities can monitor their performance in real-time, providing valuable data for predictive maintenance and system optimization. This trend aligns with the broader Internet of Things (IoT) movement, where connectivity and data analytics play a crucial role in enhancing system efficiency.

B. Sustainability and Environmental Considerations

1. Eco-friendly Materials and Manufacturing Processes

As environmental concerns grow, the capacitor industry is shifting towards more sustainable practices. Manufacturers are exploring eco-friendly materials and processes to reduce the environmental impact of capacitor production. This includes the use of biodegradable materials and energy-efficient manufacturing techniques.

2. Recycling and End-of-Life Management

Recycling and end-of-life management are becoming increasingly important in the capacitor industry. Companies are developing programs to recycle old capacitors and recover valuable materials, reducing waste and promoting a circular economy.

C. Increasing Demand for High-Performance Capacitors

1. Automotive Industry Trends

The automotive industry is undergoing a transformation with the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These technologies require high-performance capacitors for energy storage and power management, driving demand for capacitor parallel connections.

2. Telecommunications and Data Centers

The telecommunications sector is also experiencing rapid growth, particularly with the rollout of 5G technology. Data centers require efficient power management solutions, and capacitor parallel connections are essential for ensuring stable operation and minimizing energy loss.

D. Innovations in Manufacturing Processes

1. Automation and Industry 4.0

The adoption of automation and Industry 4.0 principles is revolutionizing capacitor manufacturing. Smart factories equipped with advanced robotics and data analytics are improving production efficiency, reducing costs, and enhancing product quality.

2. Advanced Testing and Quality Control

As the demand for high-performance capacitors increases, so does the need for rigorous testing and quality control. Manufacturers are investing in advanced testing technologies to ensure that capacitors meet stringent performance standards and reliability requirements.

V. Challenges Facing the Industry

A. Supply Chain Disruptions

The capacitor industry, like many others, has faced supply chain disruptions due to global events such as the COVID-19 pandemic. These disruptions have affected the availability of raw materials and components, leading to delays in production and increased costs.

B. Regulatory Compliance and Standards

As the industry evolves, manufacturers must navigate a complex landscape of regulatory compliance and standards. Ensuring that products meet safety and environmental regulations is essential for maintaining market access and consumer trust.

C. Competition from Alternative Technologies

The capacitor industry faces competition from alternative energy storage technologies, such as supercapacitors and batteries. These technologies offer unique advantages in specific applications, prompting capacitor manufacturers to innovate and differentiate their products.

VI. Future Outlook

A. Predictions for Market Growth

The capacitor parallel connection industry is poised for continued growth, driven by advancements in technology and increasing demand across various sectors. The market is expected to expand as new applications emerge, particularly in renewable energy and electric vehicles.

B. Emerging Technologies and Their Impact

Emerging technologies, such as solid-state capacitors and advanced dielectric materials, are likely to reshape the capacitor landscape. These innovations promise to deliver higher performance and reliability, further enhancing the role of capacitors in modern electrical systems.

C. Strategic Recommendations for Industry Stakeholders

To thrive in this evolving market, industry stakeholders should focus on innovation, sustainability, and collaboration. Investing in research and development, adopting eco-friendly practices, and forming strategic partnerships can help companies stay competitive and meet the changing needs of customers.

VII. Conclusion

The capacitor parallel connection industry is undergoing significant transformations driven by technological advancements, sustainability initiatives, and increasing demand for high-performance solutions. As capacitors continue to play a vital role in various applications, their evolution will shape the future of electrical systems. By embracing innovation and addressing challenges, the industry can ensure its relevance and growth in the years to come.

VIII. References

A. Academic Journals

- Journal of Electrical Engineering & Technology

- IEEE Transactions on Power Electronics

B. Industry Reports

- MarketsandMarkets: Capacitor Market Report

- Grand View Research: Global Capacitor Market Analysis

C. Market Research Studies

- Research and Markets: Capacitor Industry Trends

- Technavio: Global Capacitor Market Forecast

This blog post provides a comprehensive overview of the development trends in the capacitor parallel connection industry, highlighting the historical context, current market dynamics, and future outlook. Each section can be further expanded with specific examples and case studies to enhance the depth of the discussion.

2025-01-07

0

What are the popular models of the top 10 mainstream capacitor manufacturers?

Popular Models of the Top 10 Mainstream Capacitor Manufacturers

I. Introduction

Capacitors are essential components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to filtering signals in audio equipment. The capacitor market is significant, with a wide range of applications across industries such as consumer electronics, automotive, telecommunications, and renewable energy. This article aims to explore popular models from leading capacitor manufacturers, providing insights into their offerings and applications.

II. Overview of Capacitor Types

Capacitors come in various types, each suited for specific applications:

A. Electrolytic Capacitors

Electrolytic capacitors are polarized components that offer high capacitance values in a compact size. They are commonly used in power supply circuits and audio applications.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and known for their stability and reliability. They are widely used in high-frequency applications and decoupling circuits.

C. Film Capacitors

Film capacitors are made from thin plastic films and are known for their low loss and high stability. They are often used in audio equipment and power electronics.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance and reliability. They are commonly used in compact electronic devices, such as smartphones and tablets.

E. Supercapacitors

Supercapacitors, or ultracapacitors, offer high energy density and rapid charge/discharge capabilities. They are used in applications requiring quick bursts of energy, such as regenerative braking systems in electric vehicles.

F. Comparison of Different Types and Their Applications

Each type of capacitor has its advantages and disadvantages, making them suitable for specific applications. Understanding these differences is crucial for selecting the right capacitor for a given project.

III. Criteria for Selecting Capacitor Manufacturers

When choosing a capacitor manufacturer, several criteria should be considered:

A. Quality and Reliability

The quality of capacitors is paramount, as failures can lead to significant issues in electronic circuits. Manufacturers with a reputation for reliability are preferred.

B. Range of Products Offered

A diverse product range allows designers to find the right capacitor for their specific needs, whether it be for high-frequency applications or high-capacitance requirements.

C. Innovation and Technology

Manufacturers that invest in research and development often produce capacitors with advanced features, such as lower equivalent series resistance (ESR) and higher temperature ratings.

D. Customer Support and Service

Good customer support can be invaluable, especially when dealing with technical issues or product selection.

E. Market Reputation and Reviews

Researching a manufacturer’s reputation through reviews and industry feedback can provide insights into their reliability and product performance.

IV. Top 10 Mainstream Capacitor Manufacturers

A. Introduction to the Leading Manufacturers in the Industry

The following section highlights the top 10 capacitor manufacturers, detailing their popular models and applications.

1. Murata Manufacturing Co., Ltd.

**Overview of the Company:** Murata is a leading manufacturer of electronic components, known for its innovative solutions in capacitors and other passive components.

**Popular Models:**

GRM Series (Multilayer Ceramic Capacitors): These capacitors are widely used in smartphones and other compact devices due to their small size and high capacitance.

X5R and X7R Dielectric Capacitors: These capacitors are known for their temperature stability and are used in various applications, including power supplies and decoupling.

2. Nichicon Corporation

**Overview of the Company:** Nichicon specializes in aluminum electrolytic capacitors and is recognized for its commitment to quality and innovation.

**Popular Models:**

UHE Series (Aluminum Electrolytic Capacitors): These capacitors are designed for high-performance applications, offering low ESR and long life.

PL Series (Low-ESR Capacitors): Ideal for power supply circuits, these capacitors provide excellent performance in high-frequency applications.

3. KEMET Corporation

**Overview of the Company:** KEMET is known for its wide range of capacitor technologies, including tantalum, ceramic, and film capacitors.

**Popular Models:**

T491 Series (Tantalum Capacitors): These capacitors are designed for high reliability and are commonly used in automotive and industrial applications.

C4AE Series (Ceramic Capacitors): Known for their high capacitance and low loss, these capacitors are suitable for various electronic applications.

4. Panasonic Corporation

**Overview of the Company:** Panasonic is a global leader in electronics, offering a diverse range of capacitors for various applications.

**Popular Models:**

EEU-FR Series (Aluminum Electrolytic Capacitors): These capacitors are designed for high ripple current and long life, making them ideal for power supply applications.

ECQ Series (Film Capacitors): Known for their stability and low loss, these capacitors are widely used in audio and power electronics.

5. Vishay Intertechnology, Inc.

**Overview of the Company:** Vishay is a major manufacturer of discrete semiconductors and passive components, including capacitors.

**Popular Models:**

1812 Series (Ceramic Capacitors): These capacitors are suitable for a wide range of applications, including decoupling and filtering.

2220 Series (Film Capacitors): Known for their high voltage ratings and stability, these capacitors are used in power electronics and audio applications.

6. AVX Corporation

**Overview of the Company:** AVX specializes in passive components, including capacitors, connectors, and filters.

**Popular Models:**

0402 and 0603 Series (Multilayer Ceramic Capacitors): These small-sized capacitors are ideal for compact electronic devices, offering high capacitance in a limited space.

Tantalum Capacitors (Various Series): AVX offers a range of tantalum capacitors known for their reliability and performance in demanding applications.

7. Rubycon Corporation

**Overview of the Company:** Rubycon is known for its high-quality aluminum electrolytic and tantalum capacitors.

**Popular Models:**

ZLJ Series (Aluminum Electrolytic Capacitors): These capacitors are designed for high-performance applications, offering low ESR and long life.

16V Series (Tantalum Capacitors): Known for their compact size and high reliability, these capacitors are used in various electronic devices.

8. Elna Co., Ltd.

**Overview of the Company:** Elna specializes in audio capacitors and is recognized for its high-quality products.

**Popular Models:**

Silmic II Series (Audio Capacitors): These capacitors are designed for audio applications, providing excellent sound quality and low distortion.

RFS Series (Aluminum Electrolytic Capacitors): Known for their reliability, these capacitors are used in various electronic applications.

9. WIMA GmbH & Co. KG

**Overview of the Company:** WIMA is a leading manufacturer of film capacitors, known for their high quality and performance.

**Popular Models:**

MKS Series (Film Capacitors): These capacitors are widely used in power electronics and audio applications due to their stability and low loss.

MKP Series (Polypropylene Capacitors): Known for their high voltage ratings and reliability, these capacitors are suitable for various applications.

10. Cornell Dubilier Electronics, Inc.

**Overview of the Company:** Cornell Dubilier is a well-known manufacturer of capacitors, particularly in the film and aluminum electrolytic categories.

**Popular Models:**

940C Series (Film Capacitors): These capacitors are designed for high-performance applications, offering low ESR and high voltage ratings.

150D Series (Aluminum Electrolytic Capacitors): Known for their reliability, these capacitors are used in power supply and industrial applications.

V. Applications of Capacitors in Various Industries

Capacitors find applications across a wide range of industries:

A. Consumer Electronics

In consumer electronics, capacitors are used in power supplies, audio equipment, and signal processing circuits.

B. Automotive

Capacitors play a crucial role in automotive applications, including power management systems, infotainment, and safety features.

C. Industrial Equipment

In industrial settings, capacitors are used in motor drives, power supplies, and control systems.

D. Telecommunications

Capacitors are essential in telecommunications for signal filtering, decoupling, and power supply stabilization.

E. Renewable Energy

In renewable energy systems, capacitors are used for energy storage, smoothing out voltage fluctuations, and improving system efficiency.

VI. Future Trends in Capacitor Technology

The capacitor industry is evolving, with several trends shaping its future:

A. Advancements in Materials and Manufacturing Processes

Innovations in materials, such as the development of new dielectrics and manufacturing techniques, are leading to capacitors with improved performance and reliability.

B. The Rise of Electric Vehicles and Their Impact on Capacitor Demand

The growing demand for electric vehicles is driving the need for high-performance capacitors, particularly in energy storage and power management systems.

C. The Role of Capacitors in Renewable Energy Systems

As renewable energy sources become more prevalent, capacitors will play a vital role in energy storage and management, helping to stabilize power grids and improve efficiency.

VII. Conclusion

Selecting the right capacitor manufacturer is crucial for ensuring the reliability and performance of electronic circuits. The popular models discussed in this article highlight the diverse offerings from leading manufacturers, each catering to specific applications and industries. As technology continues to advance, capacitors will remain integral to the development of innovative electronic solutions, shaping the future of technology and industry.

VIII. References

- Manufacturer websites and product catalogs

- Industry publications and technical papers

- Market research reports on capacitor technology and trends

This comprehensive exploration of popular capacitor models from leading manufacturers provides valuable insights for engineers, designers, and anyone interested in the world of electronics.

2025-01-06

0

What are the development trends in the capacitor manufacturer industry?

Development Trends in the Capacitor Manufacturer Industry

I. Introduction

Capacitors are essential components in electronic devices, serving as energy storage units that help regulate voltage and power flow. They play a critical role in various applications, from consumer electronics to industrial machinery, making the capacitor manufacturing industry a vital sector in the global economy. This article aims to explore the development trends in the capacitor manufacturing industry, examining historical contexts, current market landscapes, technological advancements, market drivers and challenges, and future predictions.

II. Historical Context

The history of capacitor technology dates back to the 18th century with the invention of the Leyden jar, one of the first capacitors. Over the years, capacitor technology has evolved significantly, leading to the development of various types of capacitors, including ceramic, electrolytic, film, and tantalum capacitors. The manufacturing processes have also advanced, transitioning from manual assembly to automated production lines, which have increased efficiency and reduced costs. Key milestones in the industry include the introduction of new dielectric materials and the miniaturization of capacitors, enabling their use in increasingly compact electronic devices.

III. Current Market Landscape

A. Overview of the Global Capacitor Market

The global capacitor market has witnessed substantial growth in recent years, driven by the increasing demand for electronic devices. According to market research, the capacitor market is projected to reach USD 30 billion by 2025, growing at a CAGR of 5.5%. Key players in the industry include companies like Murata Manufacturing, Vishay Intertechnology, and KEMET Corporation, which dominate the market with their innovative products and extensive distribution networks.

B. Types of Capacitors and Their Applications

Capacitors come in various types, each suited for specific applications:

1. **Ceramic Capacitors**: Widely used in consumer electronics, these capacitors are known for their stability and reliability.

2. **Electrolytic Capacitors**: Commonly found in power supply circuits, they offer high capacitance values and are essential for filtering applications.

3. **Film Capacitors**: Known for their low losses and high insulation resistance, these capacitors are used in audio equipment and power electronics.

4. **Tantalum Capacitors**: These capacitors are favored in military and aerospace applications due to their reliability and performance in extreme conditions.

C. Regional Market Analysis

The capacitor market is geographically diverse, with significant activity in North America, Europe, and the Asia-Pacific region. North America is home to several leading manufacturers and benefits from a strong consumer electronics market. Europe is focusing on sustainable manufacturing practices and compliance with environmental regulations, while the Asia-Pacific region, particularly China, is experiencing rapid growth due to its booming electronics industry.

IV. Technological Advancements

A. Innovations in Capacitor Materials

Recent innovations in capacitor materials have led to the development of new dielectric materials that enhance performance and efficiency. For instance, advancements in polymer and ceramic materials have resulted in capacitors with higher capacitance values and improved thermal stability. Additionally, nanotechnology is being explored to create capacitors with smaller sizes and higher energy densities.

B. Manufacturing Process Improvements

The capacitor manufacturing industry is embracing automation and Industry 4.0 technologies to improve production efficiency. Automated assembly lines and robotics are reducing labor costs and increasing output. Furthermore, sustainable manufacturing practices are gaining traction, with companies focusing on reducing waste and energy consumption during production.

C. Miniaturization and High-Capacity Designs

As electronic devices become smaller and more powerful, the trend towards miniaturization in capacitor design is becoming increasingly important. Manufacturers are developing high-capacity capacitors that can fit into compact spaces without compromising performance. This trend is particularly relevant in the context of smartphones, wearables, and other portable devices.

V. Market Drivers and Challenges

A. Increasing Demand for Electronic Devices

The growing demand for electronic devices is a significant driver of the capacitor manufacturing industry. The rise of consumer electronics, including smartphones, tablets, and laptops, has led to an increased need for capacitors. Additionally, the expansion of electric vehicles (EVs) and renewable energy systems is creating new opportunities for capacitor manufacturers, as these technologies require advanced energy storage solutions.

B. Regulatory and Environmental Considerations

The capacitor manufacturing industry is also facing regulatory and environmental challenges. Compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations is essential for manufacturers to ensure their products are safe and environmentally friendly. There is a growing shift towards eco-friendly materials, prompting manufacturers to innovate and adapt their processes.

C. Supply Chain Challenges

The COVID-19 pandemic has highlighted vulnerabilities in global supply chains, impacting the availability of raw materials and components for capacitor manufacturing. Material shortages and sourcing issues have become prevalent, forcing manufacturers to rethink their supply chain strategies and seek alternative sources for critical materials.

VI. Future Trends and Predictions

A. Growth of Electric Vehicles and Energy Storage Systems

The future of the capacitor manufacturing industry is closely tied to the growth of electric vehicles and energy storage systems. As the demand for EVs continues to rise, capacitors will play a crucial role in power management and energy efficiency. Manufacturers are expected to invest in research and development to create capacitors that can withstand the unique demands of EV applications.

B. The Role of Capacitors in Renewable Energy Technologies

Capacitors are essential components in renewable energy technologies, such as solar and wind power systems. They help stabilize voltage and improve the efficiency of energy conversion. As the world shifts towards sustainable energy solutions, the demand for capacitors in this sector is expected to grow significantly.

C. Emerging Applications in IoT and Smart Devices

The Internet of Things (IoT) and smart devices are creating new opportunities for capacitor manufacturers. As more devices become interconnected, the need for efficient energy storage and management solutions will increase. Capacitors will be integral to the performance of these devices, driving innovation in design and materials.

D. Predictions for Market Consolidation and Mergers

As the capacitor market continues to evolve, consolidation and mergers among manufacturers are likely to occur. Companies may seek to enhance their product offerings and expand their market reach through strategic partnerships and acquisitions. This trend could lead to a more competitive landscape, with fewer but more powerful players dominating the market.

VII. Conclusion

In summary, the capacitor manufacturing industry is undergoing significant changes driven by technological advancements, increasing demand for electronic devices, and evolving regulatory landscapes. The importance of innovation and adaptation cannot be overstated, as manufacturers strive to meet the challenges and opportunities presented by the market. As we look to the future, the capacitor industry is poised for growth, with exciting developments on the horizon that will shape the next generation of electronic devices.

VIII. References

1. Market Research Reports on Capacitor Industry

2. Academic Papers on Capacitor Technology

3. Industry Reports from Leading Manufacturers

4. Articles on Emerging Trends in Electronics and Energy Storage

This blog post provides a comprehensive overview of the development trends in the capacitor manufacturing industry, highlighting the historical context, current market dynamics, technological advancements, market drivers and challenges, and future predictions. Each section is designed to offer insights into the complexities and opportunities within this vital sector.

2025-01-05

2