Popular Models of the Top 10 Mainstream Capacitor Manufacturers

I. Introduction

Capacitors are essential components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to filtering signals in audio equipment. The capacitor market is significant, with a wide range of applications across industries such as consumer electronics, automotive, telecommunications, and renewable energy. This article aims to explore popular models from leading capacitor manufacturers, providing insights into their offerings and applications.

II. Overview of Capacitor Types

Capacitors come in various types, each suited for specific applications:

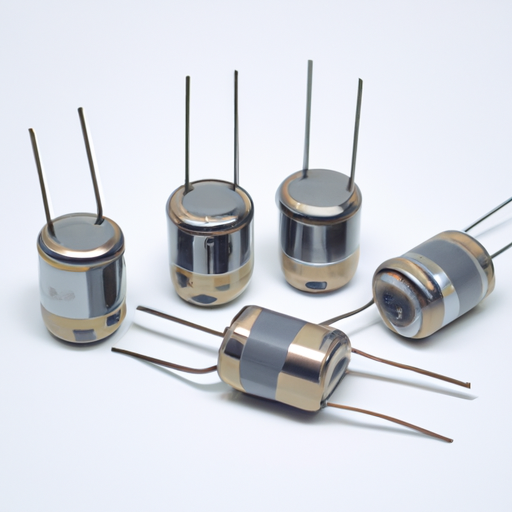

A. Electrolytic Capacitors

Electrolytic capacitors are polarized components that offer high capacitance values in a compact size. They are commonly used in power supply circuits and audio applications.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and known for their stability and reliability. They are widely used in high-frequency applications and decoupling circuits.

C. Film Capacitors

Film capacitors are made from thin plastic films and are known for their low loss and high stability. They are often used in audio equipment and power electronics.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance and reliability. They are commonly used in compact electronic devices, such as smartphones and tablets.

E. Supercapacitors

Supercapacitors, or ultracapacitors, offer high energy density and rapid charge/discharge capabilities. They are used in applications requiring quick bursts of energy, such as regenerative braking systems in electric vehicles.

F. Comparison of Different Types and Their Applications

Each type of capacitor has its advantages and disadvantages, making them suitable for specific applications. Understanding these differences is crucial for selecting the right capacitor for a given project.

III. Criteria for Selecting Capacitor Manufacturers

When choosing a capacitor manufacturer, several criteria should be considered:

A. Quality and Reliability

The quality of capacitors is paramount, as failures can lead to significant issues in electronic circuits. Manufacturers with a reputation for reliability are preferred.

B. Range of Products Offered

A diverse product range allows designers to find the right capacitor for their specific needs, whether it be for high-frequency applications or high-capacitance requirements.

C. Innovation and Technology

Manufacturers that invest in research and development often produce capacitors with advanced features, such as lower equivalent series resistance (ESR) and higher temperature ratings.

D. Customer Support and Service

Good customer support can be invaluable, especially when dealing with technical issues or product selection.

E. Market Reputation and Reviews

Researching a manufacturer’s reputation through reviews and industry feedback can provide insights into their reliability and product performance.

IV. Top 10 Mainstream Capacitor Manufacturers

A. Introduction to the Leading Manufacturers in the Industry

The following section highlights the top 10 capacitor manufacturers, detailing their popular models and applications.

1. Murata Manufacturing Co., Ltd.

**Overview of the Company:** Murata is a leading manufacturer of electronic components, known for its innovative solutions in capacitors and other passive components.

**Popular Models:**

GRM Series (Multilayer Ceramic Capacitors): These capacitors are widely used in smartphones and other compact devices due to their small size and high capacitance.

X5R and X7R Dielectric Capacitors: These capacitors are known for their temperature stability and are used in various applications, including power supplies and decoupling.

2. Nichicon Corporation

**Overview of the Company:** Nichicon specializes in aluminum electrolytic capacitors and is recognized for its commitment to quality and innovation.

**Popular Models:**

UHE Series (Aluminum Electrolytic Capacitors): These capacitors are designed for high-performance applications, offering low ESR and long life.

PL Series (Low-ESR Capacitors): Ideal for power supply circuits, these capacitors provide excellent performance in high-frequency applications.

3. KEMET Corporation

**Overview of the Company:** KEMET is known for its wide range of capacitor technologies, including tantalum, ceramic, and film capacitors.

**Popular Models:**

T491 Series (Tantalum Capacitors): These capacitors are designed for high reliability and are commonly used in automotive and industrial applications.

C4AE Series (Ceramic Capacitors): Known for their high capacitance and low loss, these capacitors are suitable for various electronic applications.

4. Panasonic Corporation

**Overview of the Company:** Panasonic is a global leader in electronics, offering a diverse range of capacitors for various applications.

**Popular Models:**

EEU-FR Series (Aluminum Electrolytic Capacitors): These capacitors are designed for high ripple current and long life, making them ideal for power supply applications.

ECQ Series (Film Capacitors): Known for their stability and low loss, these capacitors are widely used in audio and power electronics.

5. Vishay Intertechnology, Inc.

**Overview of the Company:** Vishay is a major manufacturer of discrete semiconductors and passive components, including capacitors.

**Popular Models:**

1812 Series (Ceramic Capacitors): These capacitors are suitable for a wide range of applications, including decoupling and filtering.

2220 Series (Film Capacitors): Known for their high voltage ratings and stability, these capacitors are used in power electronics and audio applications.

6. AVX Corporation

**Overview of the Company:** AVX specializes in passive components, including capacitors, connectors, and filters.

**Popular Models:**

0402 and 0603 Series (Multilayer Ceramic Capacitors): These small-sized capacitors are ideal for compact electronic devices, offering high capacitance in a limited space.

Tantalum Capacitors (Various Series): AVX offers a range of tantalum capacitors known for their reliability and performance in demanding applications.

7. Rubycon Corporation

**Overview of the Company:** Rubycon is known for its high-quality aluminum electrolytic and tantalum capacitors.

**Popular Models:**

ZLJ Series (Aluminum Electrolytic Capacitors): These capacitors are designed for high-performance applications, offering low ESR and long life.

16V Series (Tantalum Capacitors): Known for their compact size and high reliability, these capacitors are used in various electronic devices.

8. Elna Co., Ltd.

**Overview of the Company:** Elna specializes in audio capacitors and is recognized for its high-quality products.

**Popular Models:**

Silmic II Series (Audio Capacitors): These capacitors are designed for audio applications, providing excellent sound quality and low distortion.

RFS Series (Aluminum Electrolytic Capacitors): Known for their reliability, these capacitors are used in various electronic applications.

9. WIMA GmbH & Co. KG

**Overview of the Company:** WIMA is a leading manufacturer of film capacitors, known for their high quality and performance.

**Popular Models:**

MKS Series (Film Capacitors): These capacitors are widely used in power electronics and audio applications due to their stability and low loss.

MKP Series (Polypropylene Capacitors): Known for their high voltage ratings and reliability, these capacitors are suitable for various applications.

10. Cornell Dubilier Electronics, Inc.

**Overview of the Company:** Cornell Dubilier is a well-known manufacturer of capacitors, particularly in the film and aluminum electrolytic categories.

**Popular Models:**

940C Series (Film Capacitors): These capacitors are designed for high-performance applications, offering low ESR and high voltage ratings.

150D Series (Aluminum Electrolytic Capacitors): Known for their reliability, these capacitors are used in power supply and industrial applications.

V. Applications of Capacitors in Various Industries

Capacitors find applications across a wide range of industries:

A. Consumer Electronics

In consumer electronics, capacitors are used in power supplies, audio equipment, and signal processing circuits.

B. Automotive

Capacitors play a crucial role in automotive applications, including power management systems, infotainment, and safety features.

C. Industrial Equipment

In industrial settings, capacitors are used in motor drives, power supplies, and control systems.

D. Telecommunications

Capacitors are essential in telecommunications for signal filtering, decoupling, and power supply stabilization.

E. Renewable Energy

In renewable energy systems, capacitors are used for energy storage, smoothing out voltage fluctuations, and improving system efficiency.

VI. Future Trends in Capacitor Technology

The capacitor industry is evolving, with several trends shaping its future:

A. Advancements in Materials and Manufacturing Processes

Innovations in materials, such as the development of new dielectrics and manufacturing techniques, are leading to capacitors with improved performance and reliability.

B. The Rise of Electric Vehicles and Their Impact on Capacitor Demand

The growing demand for electric vehicles is driving the need for high-performance capacitors, particularly in energy storage and power management systems.

C. The Role of Capacitors in Renewable Energy Systems

As renewable energy sources become more prevalent, capacitors will play a vital role in energy storage and management, helping to stabilize power grids and improve efficiency.

VII. Conclusion

Selecting the right capacitor manufacturer is crucial for ensuring the reliability and performance of electronic circuits. The popular models discussed in this article highlight the diverse offerings from leading manufacturers, each catering to specific applications and industries. As technology continues to advance, capacitors will remain integral to the development of innovative electronic solutions, shaping the future of technology and industry.

VIII. References

- Manufacturer websites and product catalogs

- Industry publications and technical papers

- Market research reports on capacitor technology and trends

This comprehensive exploration of popular capacitor models from leading manufacturers provides valuable insights for engineers, designers, and anyone interested in the world of electronics.