CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

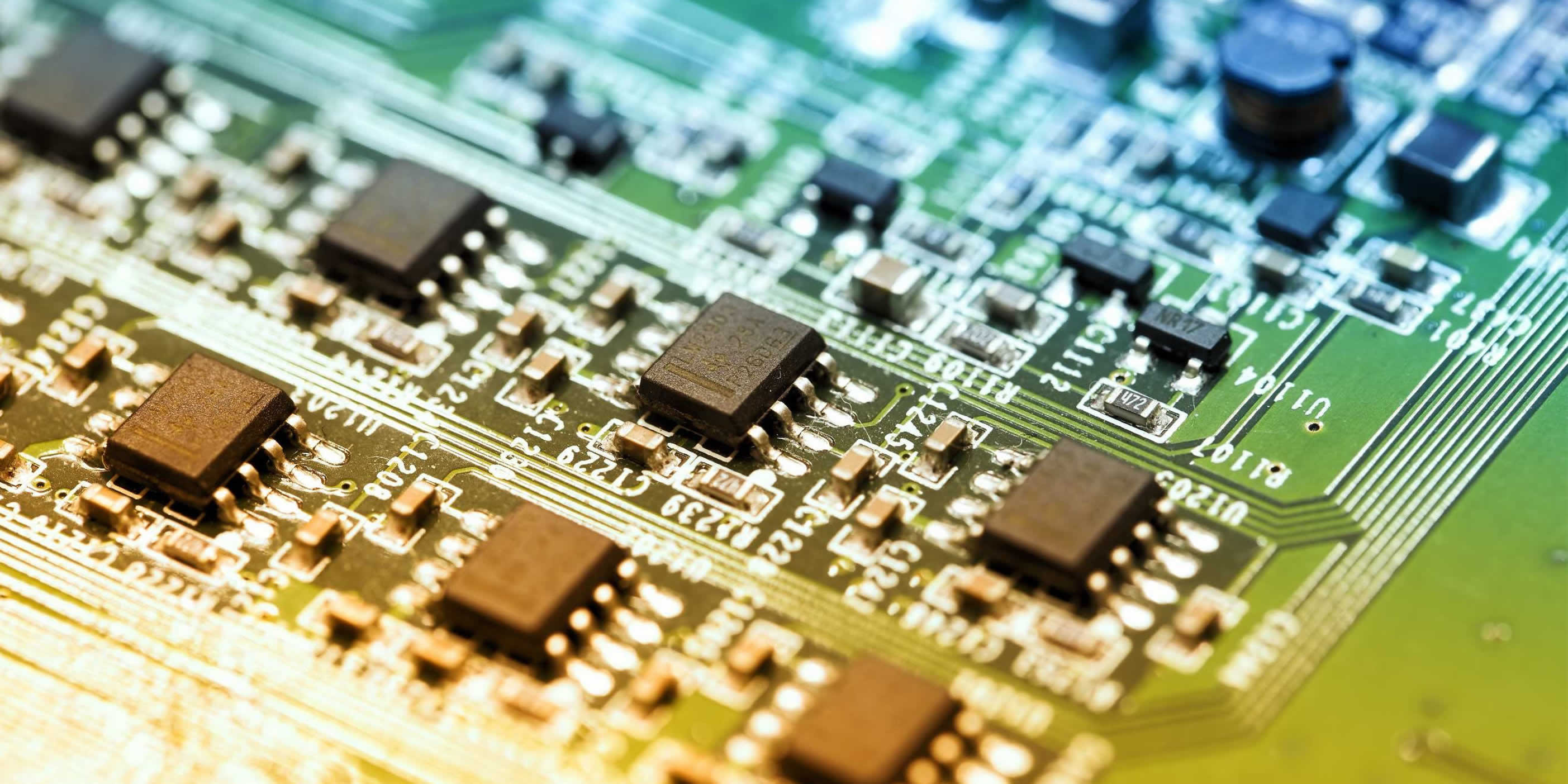

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

How to choose the capacitance of off-the-shelf capacitors?

How to Choose the Capacitance of Off-the-Shelf Capacitors

I. Introduction

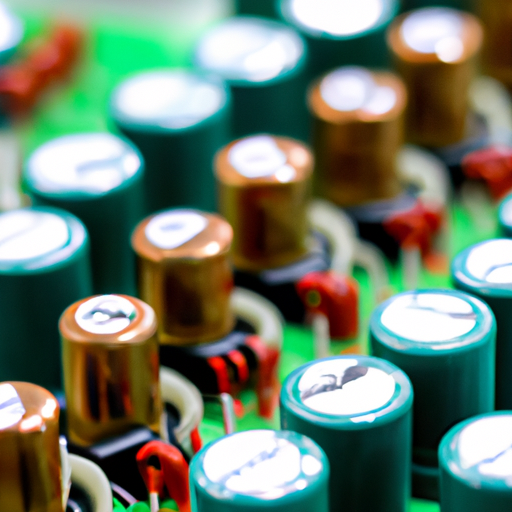

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and timing applications. Understanding how to select the appropriate capacitance for your specific needs is essential for effective circuit design. This article aims to guide you through the process of choosing the right capacitance of off-the-shelf capacitors, ensuring that your electronic projects function optimally.

II. Understanding Capacitance

A. Definition of Capacitance

Capacitance is the ability of a component to store electrical energy in an electric field. It is defined as the ratio of the electric charge stored on one plate of a capacitor to the voltage across the plates. The higher the capacitance, the more charge a capacitor can store.

B. Units of Measurement

Capacitance is measured in Farads (F), with common subunits being microfarads (µF) and nanofarads (nF). For practical applications, capacitors are often rated in microfarads or picofarads, as one Farad is a relatively large value.

C. Factors Affecting Capacitance

Several factors influence the capacitance of a capacitor:

1. **Physical Characteristics**: The size and surface area of the capacitor plates directly affect capacitance. Larger plates can store more charge.

2. **Dielectric Materials**: The type of dielectric material used between the plates also impacts capacitance. Different materials have varying dielectric constants, which determine how much charge can be stored.

3. **Voltage Ratings**: Capacitors are rated for specific voltage levels. Exceeding these ratings can lead to failure, affecting the effective capacitance in a circuit.

III. Types of Capacitors

A. Overview of Common Capacitor Types

There are several types of capacitors, each with unique characteristics and applications:

1. **Ceramic Capacitors**: Known for their small size and stability, ceramic capacitors are widely used in high-frequency applications. They are available in various capacitance values and voltage ratings.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values in a relatively small package, making them ideal for power supply applications. However, they have polarity and can be sensitive to voltage spikes.

3. **Tantalum Capacitors**: Tantalum capacitors are known for their reliability and stability, making them suitable for critical applications. They also have a higher capacitance-to-volume ratio compared to electrolytic capacitors.

4. **Film Capacitors**: These capacitors are known for their low loss and high stability. They are often used in audio applications and power electronics.

B. Characteristics and Applications of Each Type

Each capacitor type has its strengths and weaknesses, influencing the selection process based on the application. For instance, ceramic capacitors are preferred for high-frequency circuits, while electrolytic capacitors are commonly used in power supply filtering.

C. How Type Influences Capacitance Selection

The type of capacitor you choose will significantly impact the capacitance values you can select. For example, if you need a high capacitance value, electrolytic or tantalum capacitors may be more suitable than ceramic capacitors.

IV. Determining Capacitance Requirements

A. Analyzing the Circuit Design

To determine the appropriate capacitance, start by analyzing your circuit design:

1. **Identifying the Role of the Capacitor**: Understand whether the capacitor is used for filtering, decoupling, timing, or coupling signals.

2. **Understanding the Frequency Response**: The frequency at which the circuit operates will influence the capacitance value needed. Higher frequencies may require lower capacitance values.

B. Calculating Capacitance Values

1. **Using Formulas for RC Time Constants**: For timing applications, use the formula \(T = R \times C\) to calculate the time constant, where \(T\) is the time in seconds, \(R\) is the resistance in ohms, and \(C\) is the capacitance in farads.

2. **Considering Load and Source Impedance**: The impedance of the load and source can affect the required capacitance. Ensure that the capacitor can handle the expected load without significant voltage drop.

C. Practical Considerations

1. **Tolerance and Temperature Coefficients**: Capacitors come with tolerance ratings that indicate how much the actual capacitance can vary from the stated value. Additionally, temperature coefficients can affect performance in varying temperatures.

2. **Size and Form Factor Constraints**: The physical size of the capacitor may also be a limiting factor, especially in compact designs. Ensure that the selected capacitor fits within the available space.

V. Application-Specific Considerations

A. Power Supply Decoupling

1. **Importance of Low ESR Capacitors**: In power supply applications, low Equivalent Series Resistance (ESR) capacitors are crucial for stability and performance. They help reduce voltage ripple and improve transient response.

2. **Choosing Capacitance for Stability**: The capacitance value should be chosen based on the load requirements and the desired stability of the power supply.

B. Signal Coupling and Filtering

1. **Capacitance Values for Audio and RF Applications**: In audio circuits, coupling capacitors are used to block DC while allowing AC signals to pass. The capacitance value will affect the frequency response and bandwidth.

2. **Impact on Bandwidth and Signal Integrity**: In RF applications, the choice of capacitance can significantly impact signal integrity and bandwidth. Ensure that the selected capacitance aligns with the desired frequency response.

C. Timing Circuits

1. **Selecting Capacitance for Oscillators and Timers**: In timing circuits, the capacitance value directly influences the timing intervals. Choose values that provide the desired timing characteristics.

2. **Trade-offs Between Precision and Stability**: Higher precision capacitors may be required for critical timing applications, but they can come at a higher cost. Balance the need for precision with budget constraints.

VI. Sourcing Off-the-Shelf Capacitors

A. Understanding Manufacturer Specifications

1. **Reading Datasheets**: Always refer to the manufacturer's datasheets for detailed specifications, including capacitance values, voltage ratings, and temperature coefficients.

2. **Key Parameters to Consider**: Pay attention to parameters such as voltage rating, ESR, and ESL (Equivalent Series Inductance) to ensure the capacitor meets your application requirements.

B. Comparing Options from Different Suppliers

When sourcing capacitors, compare options from various suppliers to find the best fit for your needs. Consider factors such as price, availability, and lead times.

C. Importance of Quality and Reliability in Capacitor Selection

Quality and reliability are paramount when selecting capacitors, especially for critical applications. Choose reputable manufacturers and consider long-term performance and aging effects.

VII. Common Mistakes to Avoid

A. Overestimating or Underestimating Capacitance Needs

One of the most common mistakes is miscalculating the required capacitance. Take the time to analyze your circuit thoroughly to avoid issues down the line.

B. Ignoring Temperature and Voltage Derating

Always consider derating capacitors based on temperature and voltage to ensure long-term reliability. Operating close to the maximum ratings can lead to premature failure.

C. Failing to Consider Long-Term Reliability and Aging Effects

Capacitors can degrade over time, affecting their performance. Choose capacitors with a proven track record for reliability, especially in critical applications.

VIII. Conclusion

Selecting the right capacitance for off-the-shelf capacitors is a vital aspect of electronic design. By understanding the principles of capacitance, the types of capacitors available, and the specific requirements of your application, you can make informed decisions that enhance the performance and reliability of your circuits. Don’t hesitate to experiment and learn through practical application, as hands-on experience is invaluable in mastering capacitor selection.

IX. References

- Suggested readings and resources for further learning on capacitors and circuit design.

- Links to capacitor manufacturers and datasheet repositories for easy access to specifications and product information.

By following the guidelines outlined in this article, you can confidently choose the right capacitors for your electronic projects, ensuring optimal performance and reliability.

2024-12-23

0

What is the mainstream production process of high-voltage capacitors?

What is the Mainstream Production Process of High-Voltage Capacitors?

I. Introduction

High-voltage capacitors are essential components in various electrical systems, playing a critical role in energy storage, power factor correction, and voltage regulation. These capacitors are designed to operate at voltages significantly higher than standard capacitors, making them indispensable in applications such as power transmission, renewable energy systems, and industrial machinery. Understanding the production process of high-voltage capacitors is crucial for appreciating their functionality and reliability in demanding environments. This blog post will explore the mainstream production process of high-voltage capacitors, from raw materials to distribution.

II. Raw Materials

A. Types of Materials Used

The production of high-voltage capacitors begins with the selection of appropriate raw materials. The two primary categories of materials used are dielectric and conductive materials.

1. **Dielectric Materials**: The dielectric material is crucial for the capacitor's performance, as it determines the capacitor's ability to store electrical energy. Common dielectric materials include polypropylene and polyester, known for their excellent electrical insulation properties and thermal stability. These materials are chosen based on their dielectric strength, loss factor, and temperature stability.

2. **Conductive Materials**: The electrodes of high-voltage capacitors are typically made from conductive materials such as aluminum or copper. These metals are selected for their high conductivity, which is essential for efficient energy transfer. The choice of conductive material can also affect the capacitor's overall weight, cost, and performance.

B. Quality Control of Raw Materials

Quality control is a critical aspect of the production process. Raw materials must meet stringent specifications to ensure the reliability and performance of the final product. Manufacturers often conduct tests to assess the dielectric strength, thermal properties, and mechanical integrity of the materials before they are used in production.

C. Sourcing and Sustainability Considerations

In recent years, there has been a growing emphasis on sustainability in the sourcing of raw materials. Manufacturers are increasingly looking for suppliers who adhere to environmentally friendly practices and can provide materials with a lower carbon footprint. This shift not only benefits the environment but also enhances the manufacturer's reputation and compliance with regulatory standards.

III. Design and Engineering

A. Specifications and Requirements for High-Voltage Capacitors

The design of high-voltage capacitors involves careful consideration of various specifications and requirements. These include voltage ratings, capacitance values, temperature ranges, and physical dimensions. Engineers must ensure that the design can withstand the electrical and thermal stresses encountered in real-world applications.

B. Role of Computer-Aided Design (CAD) in Capacitor Design

Computer-aided design (CAD) software plays a vital role in the design process. Engineers use CAD tools to create detailed models of the capacitor, allowing for precise calculations and simulations. This technology enables designers to optimize the capacitor's performance and identify potential issues before moving to the manufacturing stage.

C. Prototyping and Testing of Designs

Once the design is finalized, prototypes are created for testing. These prototypes undergo rigorous evaluation to assess their performance under various conditions. Testing may include electrical, thermal, and mechanical assessments to ensure that the capacitor meets all specifications and can operate reliably in its intended application.

IV. Manufacturing Process

The manufacturing process of high-voltage capacitors involves several key steps, each critical to ensuring the quality and performance of the final product.

A. Dielectric Film Production

1. **Film Extrusion Process**: The first step in manufacturing high-voltage capacitors is the production of the dielectric film. This is typically done through a film extrusion process, where raw polymer materials are melted and formed into thin films. The thickness of the film is crucial, as it directly impacts the capacitor's voltage rating and capacitance.

2. **Thickness and Quality Control**: Quality control measures are implemented during the film production process to ensure uniform thickness and material properties. Any defects in the dielectric film can lead to failures in the final capacitor, making this step critical.

B. Electrode Preparation

1. **Metal Deposition Techniques**: After the dielectric film is produced, the next step is preparing the electrodes. This often involves metal deposition techniques, such as vacuum deposition or sputtering, to apply a thin layer of conductive material onto the dielectric film. The choice of technique can affect the adhesion and conductivity of the electrodes.

2. **Surface Treatment for Adhesion**: To enhance the adhesion between the dielectric and the electrodes, surface treatments may be applied. These treatments can include chemical etching or plasma treatment, which improve the surface properties and ensure a strong bond.

C. Capacitor Assembly

1. **Layering of Dielectric and Electrodes**: The assembly process involves layering the dielectric film and electrodes. This can be done through winding or stacking methods, depending on the design of the capacitor. The arrangement of these layers is crucial for achieving the desired capacitance and voltage rating.

2. **Winding or Stacking Methods**: In winding methods, the dielectric film is rolled with the electrodes to create a cylindrical capacitor. In stacking methods, layers are stacked flat to form a rectangular capacitor. Each method has its advantages and is chosen based on the specific application requirements.

D. Encapsulation and Sealing

1. **Use of Resin or Other Materials for Protection**: Once the capacitor is assembled, it is encapsulated to protect it from environmental factors such as moisture and dust. This is typically done using resin or other protective materials that provide insulation and mechanical support.

2. **Importance of Moisture and Environmental Protection**: Proper encapsulation is essential for ensuring the long-term reliability of high-voltage capacitors. Moisture ingress can lead to dielectric breakdown and failure, making this step critical in the manufacturing process.

V. Testing and Quality Assurance

A. Electrical Testing

Once the capacitors are manufactured, they undergo a series of electrical tests to ensure they meet performance specifications. This includes measuring capacitance, voltage rating, and leakage current. These tests help identify any defects or inconsistencies in the capacitors.

B. Mechanical Testing

Mechanical testing is also conducted to assess the capacitor's ability to withstand physical stresses. This may include pressure testing, temperature cycling, and vibration tests to simulate real-world conditions.

C. Long-Term Reliability Testing

Long-term reliability testing is crucial for high-voltage capacitors, as they are often used in critical applications. These tests evaluate the capacitor's performance over extended periods, helping manufacturers identify potential failure modes and improve design robustness.

D. Compliance with Industry Standards

Manufacturers must ensure that their high-voltage capacitors comply with industry standards, such as those set by the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL). Compliance with these standards is essential for ensuring safety and reliability in various applications.

VI. Packaging and Distribution

A. Packaging Materials and Methods

Once testing is complete, high-voltage capacitors are carefully packaged to prevent damage during transportation. Packaging materials must provide adequate protection while being lightweight and cost-effective. Manufacturers often use custom packaging solutions to ensure the safe delivery of their products.

B. Logistics and Supply Chain Considerations

Efficient logistics and supply chain management are critical for the timely delivery of high-voltage capacitors. Manufacturers must coordinate with suppliers, distributors, and customers to ensure that products are delivered on time and in good condition.

C. Importance of Proper Handling During Transportation

Proper handling during transportation is essential to prevent damage to the capacitors. This includes training personnel on handling procedures and using appropriate equipment to minimize the risk of impact or vibration during transit.

VII. Conclusion

The production process of high-voltage capacitors is a complex and meticulous endeavor that involves multiple stages, from raw material selection to final testing and distribution. Each step is critical to ensuring the reliability and performance of these essential components in electrical systems. As technology advances, manufacturers are continually seeking ways to improve the efficiency and sustainability of their production processes. High-voltage capacitors will continue to play a vital role in advancing electrical systems, supporting the transition to renewable energy, and enhancing the reliability of power transmission.

VIII. References

A. Suggested readings and resources for further exploration include industry publications, technical standards, and academic research on capacitor technology.

B. Industry standards and guidelines for high-voltage capacitors can be found through organizations such as the IEC and UL, which provide essential frameworks for ensuring safety and performance in capacitor manufacturing.

2024-12-22

2

What are the development trends in the capacitor bank industry?

Development Trends in the Capacitor Bank Industry

I. Introduction

Capacitor banks are essential components in electrical systems, designed to improve power factor, stabilize voltage, and enhance the efficiency of electrical networks. By storing and releasing electrical energy, they play a crucial role in managing reactive power, which is vital for the smooth operation of electrical equipment. As the demand for reliable and efficient power systems grows, the capacitor bank industry has evolved significantly, adapting to new technologies and market needs. This blog post explores the development trends shaping the capacitor bank industry, highlighting technological advancements, market dynamics, and future outlooks.

II. Historical Context

The technology behind capacitor banks has undergone substantial evolution since its inception. Initially, capacitor banks were simple, fixed installations used primarily for power factor correction in industrial settings. Over the decades, advancements in materials and design have led to the development of more sophisticated systems, including automatic and synchronous capacitor banks. Key milestones, such as the introduction of digital control systems and the integration of capacitor banks with renewable energy sources, have transformed their applications and capabilities.

Historically, capacitor banks were limited in their functionality, primarily serving to correct power factor issues in large industrial plants. However, as electrical grids became more complex and the integration of renewable energy sources increased, the need for more dynamic and responsive capacitor bank systems emerged. This shift has paved the way for innovations that enhance the performance and versatility of capacitor banks.

III. Current Market Landscape

A. Overview of the Global Capacitor Bank Market

The global capacitor bank market has experienced significant growth in recent years, driven by the increasing demand for efficient power management solutions. According to industry reports, the market size is projected to reach several billion dollars by the end of the decade, with a compound annual growth rate (CAGR) of over 5%. Key players in the market include established manufacturers and emerging companies, each vying for market share through innovation and strategic partnerships.

B. Types of Capacitor Banks

Capacitor banks can be categorized into three main types:

1. **Fixed Capacitor Banks**: These are static installations that provide a constant level of reactive power compensation. They are commonly used in industrial applications where power factor correction is needed.

2. **Automatic Capacitor Banks**: Equipped with control systems, these banks can adjust their output based on real-time demand, making them ideal for dynamic environments where load conditions fluctuate.

3. **Synchronous Capacitor Banks**: These systems not only provide reactive power but also contribute to voltage regulation and stability in the grid. They are often used in large power generation facilities and transmission networks.

C. Applications Across Various Sectors

Capacitor banks find applications in diverse sectors, including:

1. **Power Generation**: They are crucial for maintaining voltage levels and improving the efficiency of power plants.

2. **Industrial Applications**: Factories and manufacturing plants utilize capacitor banks to enhance power factor and reduce energy costs.

3. **Renewable Energy Integration**: As the share of renewable energy sources like wind and solar increases, capacitor banks play a vital role in stabilizing the grid and managing the variability of these energy sources.

IV. Development Trends in the Capacitor Bank Industry

A. Technological Advancements

The capacitor bank industry is witnessing rapid technological advancements that are reshaping its landscape.

1. **Smart Capacitor Banks and Automation**: The integration of smart technologies allows for real-time monitoring and control of capacitor banks. Automated systems can adjust the output based on grid conditions, enhancing efficiency and reliability.

2. **Enhanced Materials and Designs**: Innovations in materials, such as advanced dielectrics and improved insulation, have led to more compact and efficient capacitor bank designs. These advancements not only improve performance but also reduce the environmental footprint of capacitor banks.

3. **Integration with Energy Management Systems**: Capacitor banks are increasingly being integrated with energy management systems (EMS) to optimize their operation within the broader electrical network. This integration allows for better coordination between generation, storage, and consumption.

B. Growing Demand for Renewable Energy

The global shift towards renewable energy sources is a significant driver of change in the capacitor bank industry.

1. **Role of Capacitor Banks in Wind and Solar Energy Systems**: Capacitor banks are essential for managing the intermittent nature of renewable energy sources. They help stabilize voltage levels and provide reactive power support, ensuring that the grid remains stable despite fluctuations in generation.

2. **Grid Stability and Energy Storage Solutions**: As more renewable energy is integrated into the grid, the need for effective energy storage solutions becomes critical. Capacitor banks can complement battery storage systems by providing rapid response capabilities for voltage support.

C. Regulatory and Environmental Considerations

The capacitor bank industry is also influenced by regulatory and environmental factors.

1. **Impact of Regulations on Capacitor Bank Design and Usage**: Governments worldwide are implementing stricter regulations aimed at improving energy efficiency and reducing carbon emissions. These regulations are pushing manufacturers to develop more efficient and environmentally friendly capacitor bank solutions.

2. **Focus on Energy Efficiency and Sustainability**: There is a growing emphasis on sustainability within the industry. Manufacturers are exploring ways to reduce the environmental impact of capacitor banks, from production processes to end-of-life disposal.

D. Innovations in Manufacturing Processes

The manufacturing processes for capacitor banks are evolving to meet the demands of a changing market.

1. **Adoption of Advanced Manufacturing Technologies**: Techniques such as automation, robotics, and additive manufacturing are being adopted to enhance production efficiency and reduce costs.

2. **Cost Reduction Strategies and Efficiency Improvements**: Manufacturers are continuously seeking ways to lower production costs while maintaining high-quality standards. This includes optimizing supply chains and leveraging economies of scale.

V. Challenges Facing the Capacitor Bank Industry

Despite the positive trends, the capacitor bank industry faces several challenges.

A. Competition from Alternative Technologies

As the energy landscape evolves, capacitor banks are competing with alternative technologies, such as battery storage and flywheels, which offer similar benefits in terms of power management and stability.

B. Supply Chain Disruptions and Material Shortages

Recent global events have highlighted vulnerabilities in supply chains, leading to material shortages and increased costs for manufacturers. This can impact the availability and pricing of capacitor banks.

C. Need for Skilled Workforce and Training

The rapid pace of technological advancement necessitates a skilled workforce capable of operating and maintaining advanced capacitor bank systems. There is a growing need for training programs to equip workers with the necessary skills.

VI. Future Outlook

A. Predictions for Market Growth and Technological Advancements

The capacitor bank market is expected to continue its growth trajectory, driven by increasing demand for efficient power management solutions and the integration of renewable energy sources. Technological advancements will further enhance the capabilities of capacitor banks, making them more versatile and efficient.

B. Potential Impact of Emerging Technologies

Emerging technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), are poised to revolutionize the capacitor bank industry. These technologies can enable predictive maintenance, optimize performance, and enhance the overall efficiency of electrical systems.

C. Strategic Recommendations for Industry Stakeholders

To thrive in this evolving landscape, industry stakeholders should focus on innovation, collaboration, and sustainability. Investing in research and development, forming strategic partnerships, and prioritizing environmentally friendly practices will be crucial for long-term success.

VII. Conclusion

In summary, the capacitor bank industry is undergoing significant transformation driven by technological advancements, growing demand for renewable energy, and regulatory pressures. As the industry adapts to these changes, innovation and adaptation will be key to navigating challenges and seizing opportunities. The future of capacitor banks is bright, with the potential to play a pivotal role in the evolving energy landscape, ensuring stability, efficiency, and sustainability in electrical systems. As we move forward, the importance of capacitor banks in supporting a reliable and resilient energy infrastructure cannot be overstated.

2024-12-20

2