Development Trends in the Capacitor Bank Industry

I. Introduction

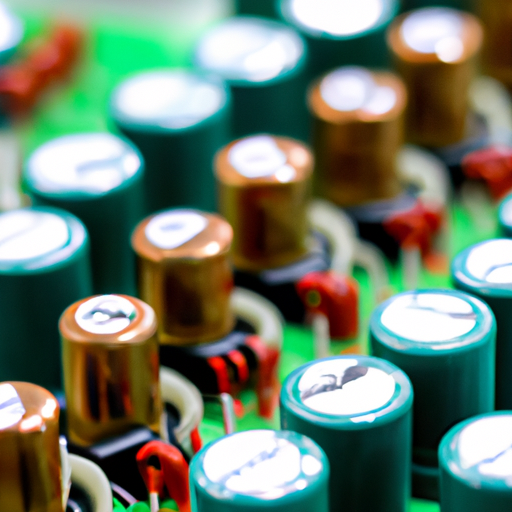

Capacitor banks are essential components in electrical systems, designed to improve power factor, stabilize voltage, and enhance the efficiency of electrical networks. By storing and releasing electrical energy, they play a crucial role in managing reactive power, which is vital for the smooth operation of electrical equipment. As the demand for reliable and efficient power systems grows, the capacitor bank industry has evolved significantly, adapting to new technologies and market needs. This blog post explores the development trends shaping the capacitor bank industry, highlighting technological advancements, market dynamics, and future outlooks.

II. Historical Context

The technology behind capacitor banks has undergone substantial evolution since its inception. Initially, capacitor banks were simple, fixed installations used primarily for power factor correction in industrial settings. Over the decades, advancements in materials and design have led to the development of more sophisticated systems, including automatic and synchronous capacitor banks. Key milestones, such as the introduction of digital control systems and the integration of capacitor banks with renewable energy sources, have transformed their applications and capabilities.

Historically, capacitor banks were limited in their functionality, primarily serving to correct power factor issues in large industrial plants. However, as electrical grids became more complex and the integration of renewable energy sources increased, the need for more dynamic and responsive capacitor bank systems emerged. This shift has paved the way for innovations that enhance the performance and versatility of capacitor banks.

III. Current Market Landscape

A. Overview of the Global Capacitor Bank Market

The global capacitor bank market has experienced significant growth in recent years, driven by the increasing demand for efficient power management solutions. According to industry reports, the market size is projected to reach several billion dollars by the end of the decade, with a compound annual growth rate (CAGR) of over 5%. Key players in the market include established manufacturers and emerging companies, each vying for market share through innovation and strategic partnerships.

B. Types of Capacitor Banks

Capacitor banks can be categorized into three main types:

1. **Fixed Capacitor Banks**: These are static installations that provide a constant level of reactive power compensation. They are commonly used in industrial applications where power factor correction is needed.

2. **Automatic Capacitor Banks**: Equipped with control systems, these banks can adjust their output based on real-time demand, making them ideal for dynamic environments where load conditions fluctuate.

3. **Synchronous Capacitor Banks**: These systems not only provide reactive power but also contribute to voltage regulation and stability in the grid. They are often used in large power generation facilities and transmission networks.

C. Applications Across Various Sectors

Capacitor banks find applications in diverse sectors, including:

1. **Power Generation**: They are crucial for maintaining voltage levels and improving the efficiency of power plants.

2. **Industrial Applications**: Factories and manufacturing plants utilize capacitor banks to enhance power factor and reduce energy costs.

3. **Renewable Energy Integration**: As the share of renewable energy sources like wind and solar increases, capacitor banks play a vital role in stabilizing the grid and managing the variability of these energy sources.

IV. Development Trends in the Capacitor Bank Industry

A. Technological Advancements

The capacitor bank industry is witnessing rapid technological advancements that are reshaping its landscape.

1. **Smart Capacitor Banks and Automation**: The integration of smart technologies allows for real-time monitoring and control of capacitor banks. Automated systems can adjust the output based on grid conditions, enhancing efficiency and reliability.

2. **Enhanced Materials and Designs**: Innovations in materials, such as advanced dielectrics and improved insulation, have led to more compact and efficient capacitor bank designs. These advancements not only improve performance but also reduce the environmental footprint of capacitor banks.

3. **Integration with Energy Management Systems**: Capacitor banks are increasingly being integrated with energy management systems (EMS) to optimize their operation within the broader electrical network. This integration allows for better coordination between generation, storage, and consumption.

B. Growing Demand for Renewable Energy

The global shift towards renewable energy sources is a significant driver of change in the capacitor bank industry.

1. **Role of Capacitor Banks in Wind and Solar Energy Systems**: Capacitor banks are essential for managing the intermittent nature of renewable energy sources. They help stabilize voltage levels and provide reactive power support, ensuring that the grid remains stable despite fluctuations in generation.

2. **Grid Stability and Energy Storage Solutions**: As more renewable energy is integrated into the grid, the need for effective energy storage solutions becomes critical. Capacitor banks can complement battery storage systems by providing rapid response capabilities for voltage support.

C. Regulatory and Environmental Considerations

The capacitor bank industry is also influenced by regulatory and environmental factors.

1. **Impact of Regulations on Capacitor Bank Design and Usage**: Governments worldwide are implementing stricter regulations aimed at improving energy efficiency and reducing carbon emissions. These regulations are pushing manufacturers to develop more efficient and environmentally friendly capacitor bank solutions.

2. **Focus on Energy Efficiency and Sustainability**: There is a growing emphasis on sustainability within the industry. Manufacturers are exploring ways to reduce the environmental impact of capacitor banks, from production processes to end-of-life disposal.

D. Innovations in Manufacturing Processes

The manufacturing processes for capacitor banks are evolving to meet the demands of a changing market.

1. **Adoption of Advanced Manufacturing Technologies**: Techniques such as automation, robotics, and additive manufacturing are being adopted to enhance production efficiency and reduce costs.

2. **Cost Reduction Strategies and Efficiency Improvements**: Manufacturers are continuously seeking ways to lower production costs while maintaining high-quality standards. This includes optimizing supply chains and leveraging economies of scale.

V. Challenges Facing the Capacitor Bank Industry

Despite the positive trends, the capacitor bank industry faces several challenges.

A. Competition from Alternative Technologies

As the energy landscape evolves, capacitor banks are competing with alternative technologies, such as battery storage and flywheels, which offer similar benefits in terms of power management and stability.

B. Supply Chain Disruptions and Material Shortages

Recent global events have highlighted vulnerabilities in supply chains, leading to material shortages and increased costs for manufacturers. This can impact the availability and pricing of capacitor banks.

C. Need for Skilled Workforce and Training

The rapid pace of technological advancement necessitates a skilled workforce capable of operating and maintaining advanced capacitor bank systems. There is a growing need for training programs to equip workers with the necessary skills.

VI. Future Outlook

A. Predictions for Market Growth and Technological Advancements

The capacitor bank market is expected to continue its growth trajectory, driven by increasing demand for efficient power management solutions and the integration of renewable energy sources. Technological advancements will further enhance the capabilities of capacitor banks, making them more versatile and efficient.

B. Potential Impact of Emerging Technologies

Emerging technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), are poised to revolutionize the capacitor bank industry. These technologies can enable predictive maintenance, optimize performance, and enhance the overall efficiency of electrical systems.

C. Strategic Recommendations for Industry Stakeholders

To thrive in this evolving landscape, industry stakeholders should focus on innovation, collaboration, and sustainability. Investing in research and development, forming strategic partnerships, and prioritizing environmentally friendly practices will be crucial for long-term success.

VII. Conclusion

In summary, the capacitor bank industry is undergoing significant transformation driven by technological advancements, growing demand for renewable energy, and regulatory pressures. As the industry adapts to these changes, innovation and adaptation will be key to navigating challenges and seizing opportunities. The future of capacitor banks is bright, with the potential to play a pivotal role in the evolving energy landscape, ensuring stability, efficiency, and sustainability in electrical systems. As we move forward, the importance of capacitor banks in supporting a reliable and resilient energy infrastructure cannot be overstated.