CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

What is the current status of the capacitor discharge industry?

What is the Current Status of the Capacitor Discharge Industry?

I. Introduction

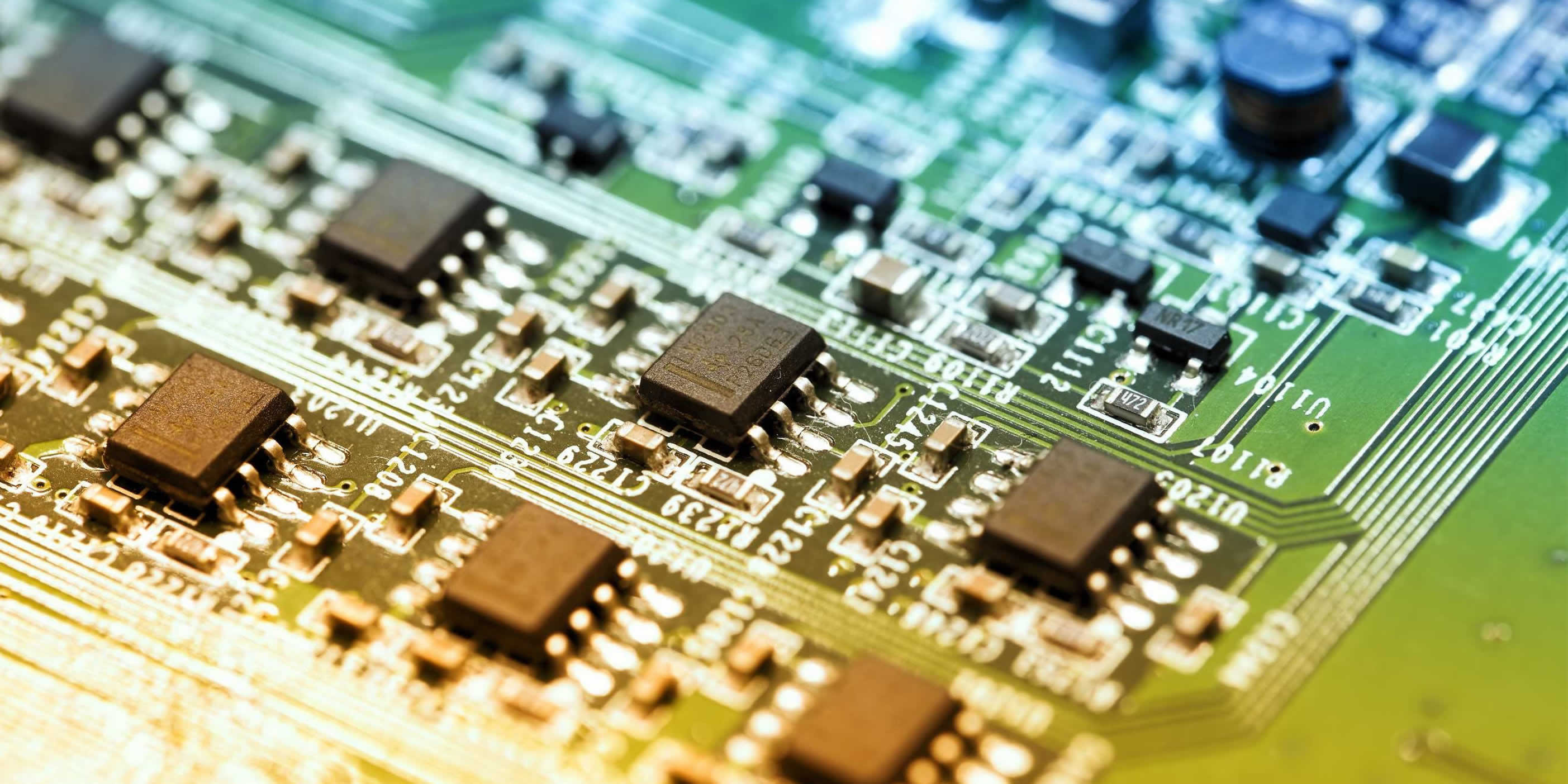

Capacitor discharge is a fundamental process in which electrical energy stored in a capacitor is released in a controlled manner. This mechanism plays a crucial role in various industries, from power electronics to automotive applications. As technology continues to evolve, the capacitor discharge industry is experiencing significant changes, driven by advancements in technology, shifts towards renewable energy, and the growing demand for electric vehicles (EVs). This article aims to provide an in-depth overview of the current status of the capacitor discharge industry, exploring its technology, trends, market dynamics, challenges, and future outlook.

II. Overview of Capacitor Discharge Technology

A. Explanation of Capacitor Discharge Mechanism

Capacitors store electrical energy in an electric field, created by a pair of conductive plates separated by an insulating material. When a circuit is completed, the stored energy can be discharged rapidly, providing a burst of power. This discharge mechanism is essential in applications requiring quick energy release, such as in flash photography, power supplies, and motor drives.

B. Types of Capacitors Used in Discharge Applications

1. **Electrolytic Capacitors**: Known for their high capacitance values, electrolytic capacitors are widely used in power supply circuits. They are polarized, meaning they must be connected in the correct direction to function properly.

2. **Film Capacitors**: These capacitors are known for their stability and low loss characteristics. They are often used in applications requiring high reliability, such as in audio equipment and power electronics.

3. **Ceramic Capacitors**: With their small size and high-frequency performance, ceramic capacitors are commonly used in consumer electronics and RF applications. They are non-polarized and can handle high voltages.

C. Applications of Capacitor Discharge

1. **Power Electronics**: Capacitor discharge is critical in power electronics, where it helps regulate voltage and current in various devices, including inverters and converters.

2. **Automotive Industry**: Capacitors are used in automotive applications for energy storage, power management, and in systems like anti-lock braking systems (ABS) and airbag deployment.

3. **Consumer Electronics**: From smartphones to televisions, capacitors play a vital role in energy storage and power supply management, ensuring devices operate efficiently.

4. **Industrial Equipment**: Capacitors are essential in industrial machinery for energy storage, motor starting, and power factor correction.

III. Current Trends in the Capacitor Discharge Industry

A. Technological Advancements

1. **Miniaturization of Capacitors**: As electronic devices become smaller and more compact, the demand for miniaturized capacitors has increased. Manufacturers are developing smaller capacitors without compromising performance.

2. **Enhanced Energy Density**: Innovations in materials and design are leading to capacitors with higher energy densities, allowing for more energy storage in smaller packages.

3. **Improved Discharge Rates**: Advances in capacitor technology are enabling faster discharge rates, which are crucial for applications requiring quick bursts of energy.

B. Shift Towards Renewable Energy

1. **Role of Capacitors in Energy Storage Systems**: Capacitors are increasingly being integrated into energy storage systems, providing a means to store and release energy generated from renewable sources.

2. **Integration with Solar and Wind Energy**: Capacitors are used in conjunction with solar panels and wind turbines to smooth out power delivery and enhance system efficiency.

C. Growing Demand in Electric Vehicles (EVs)

1. **Capacitor Discharge in EV Charging Systems**: Capacitors are essential in EV charging systems, where they help manage power delivery and improve charging efficiency.

2. **Impact on Battery Technology**: The rise of EVs is driving innovations in capacitor technology, as manufacturers seek to develop hybrid systems that combine capacitors and batteries for optimal performance.

IV. Market Analysis

A. Global Market Size and Growth Projections

The global capacitor discharge market is experiencing robust growth, driven by the increasing demand for electronic devices, renewable energy solutions, and electric vehicles. According to market research, the capacitor market is projected to grow at a compound annual growth rate (CAGR) of over 6% in the coming years.

B. Key Players in the Capacitor Discharge Industry

1. **Major Manufacturers**: Leading companies in the capacitor discharge industry include Panasonic, Vishay Intertechnology, and Murata Manufacturing. These companies are at the forefront of innovation, continuously developing new products to meet market demands.

2. **Emerging Startups**: A number of startups are entering the market, focusing on niche applications and innovative capacitor technologies. These companies are often agile and can quickly adapt to changing market needs.

C. Regional Market Insights

1. **North America**: The North American market is characterized by a strong presence of major manufacturers and a growing demand for advanced electronic devices.

2. **Europe**: Europe is witnessing significant growth in the capacitor discharge market, driven by the increasing adoption of renewable energy and electric vehicles.

3. **Asia-Pacific**: The Asia-Pacific region is the largest market for capacitors, with countries like China and Japan leading in production and consumption due to their robust electronics manufacturing sectors.

V. Challenges Facing the Capacitor Discharge Industry

A. Supply Chain Issues

1. **Raw Material Shortages**: The capacitor industry is facing challenges related to the availability of raw materials, which can impact production and lead to increased costs.

2. **Manufacturing Disruptions**: Global events, such as the COVID-19 pandemic, have caused disruptions in manufacturing, affecting the supply chain and delivery timelines.

B. Environmental Concerns

1. **Disposal and Recycling of Capacitors**: The disposal of capacitors poses environmental challenges, as some types contain hazardous materials. The industry is under pressure to develop sustainable disposal and recycling methods.

2. **Regulatory Compliance**: Stricter regulations regarding environmental impact are forcing manufacturers to adapt their processes and materials to comply with new standards.

C. Competition from Alternative Technologies

1. **Supercapacitors**: Supercapacitors are emerging as a competitive technology, offering higher power density and faster charge/discharge rates compared to traditional capacitors.

2. **Battery Technologies**: Advances in battery technology, particularly lithium-ion batteries, pose a challenge to the capacitor industry, as they are often preferred for energy storage applications.

VI. Future Outlook

A. Innovations on the Horizon

1. **Research and Development Trends**: Ongoing research in materials science and engineering is expected to lead to the development of new capacitor technologies with enhanced performance characteristics.

2. **Potential Breakthroughs in Capacitor Technology**: Innovations such as solid-state capacitors and organic capacitors may revolutionize the industry, offering improved efficiency and sustainability.

B. Predictions for Market Growth

The capacitor discharge market is expected to continue its upward trajectory, driven by the increasing demand for energy-efficient solutions and the integration of renewable energy sources.

C. Strategic Recommendations for Industry Stakeholders

To remain competitive, industry stakeholders should focus on innovation, sustainability, and collaboration. Investing in research and development, exploring new materials, and forming partnerships with renewable energy companies can help drive growth and address emerging challenges.

VII. Conclusion

In summary, the capacitor discharge industry is at a pivotal point, characterized by rapid technological advancements, growing demand in various sectors, and significant challenges. As the world moves towards a more sustainable future, the role of capacitors in energy storage and management will become increasingly important. Continued research and development will be essential to drive innovation and ensure that the industry can meet the evolving needs of consumers and businesses alike. Stakeholders are encouraged to invest in new technologies and sustainable practices to capitalize on the opportunities presented by this dynamic industry.

VIII. References

A comprehensive list of academic journals, industry reports, and market research publications would be included here to support the information presented in the article.

---

This blog post provides a detailed overview of the current status of the capacitor discharge industry, highlighting its significance, trends, market dynamics, challenges, and future outlook. Each section is designed to inform and engage readers, offering insights into a critical component of modern technology.

2025-01-10

0

What product types do capacitor voltages include?

What Product Types Do Capacitor Voltages Include?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to filtering signals in audio equipment. One of the most critical aspects of capacitors is their voltage rating, which indicates the maximum voltage a capacitor can handle safely. Understanding capacitor voltage ratings is essential for selecting the right capacitor for specific applications, ensuring reliability and performance. This article aims to explore the different types of capacitors based on their voltage ratings, their applications, and the importance of adhering to these ratings.

II. Understanding Capacitor Voltage Ratings

A. Explanation of Voltage Rating

The voltage rating of a capacitor is the maximum voltage that can be applied across its terminals without risking failure. Exceeding this voltage can lead to dielectric breakdown, resulting in catastrophic failure, which may include short circuits, explosions, or fire. The voltage rating is significant because it directly influences the capacitor's performance and longevity.

B. Factors Influencing Voltage Ratings

Several factors influence the voltage ratings of capacitors:

1. **Dielectric Material**: The type of dielectric material used in a capacitor significantly affects its voltage rating. Materials like ceramic, tantalum, and electrolytic have different dielectric strengths, which determine how much voltage they can withstand.

2. **Capacitor Construction**: The physical construction of the capacitor, including its size, shape, and the way the dielectric is layered, also impacts its voltage rating. For instance, larger capacitors may have higher voltage ratings due to their ability to dissipate heat more effectively.

3. **Environmental Conditions**: Temperature, humidity, and other environmental factors can affect a capacitor's performance and voltage rating. Capacitors are often rated for specific temperature ranges, and exceeding these can lead to reduced performance or failure.

III. Types of Capacitors Based on Voltage Ratings

Capacitors can be categorized into three main types based on their voltage ratings: low-voltage, medium-voltage, and high-voltage capacitors.

A. Low-Voltage Capacitors

Low-voltage capacitors are designed to operate at voltages typically below 100V. They are widely used in consumer electronics and other applications where high voltage is not a concern.

1. **Definition and Applications**: Low-voltage capacitors are commonly found in devices such as smartphones, televisions, and audio equipment, where they help filter signals and stabilize power supply.

2. **Common Types**:

- **Ceramic Capacitors**: These are popular for their small size and reliability. They are often used in high-frequency applications due to their low equivalent series resistance (ESR).

- **Electrolytic Capacitors**: Known for their high capacitance values, electrolytic capacitors are often used in power supply circuits to smooth out voltage fluctuations.

- **Film Capacitors**: These capacitors are known for their stability and low loss, making them suitable for audio and RF applications.

B. Medium-Voltage Capacitors

Medium-voltage capacitors operate at voltages ranging from 100V to 1,000V. They are commonly used in industrial applications and power distribution systems.

1. **Definition and Applications**: Medium-voltage capacitors are essential in applications such as motor control, power factor correction, and energy storage systems.

2. **Common Types**:

- **Power Capacitors**: These are used in power systems to improve power factor and voltage stability.

- **Motor Run Capacitors**: These capacitors are used in single-phase motors to improve efficiency and performance.

- **Snubber Capacitors**: Employed to protect circuits from voltage spikes, snubber capacitors are crucial in switching applications.

C. High-Voltage Capacitors

High-voltage capacitors are designed to handle voltages above 1,000V. They are used in specialized applications, including power transmission and high-energy storage systems.

1. **Definition and Applications**: High-voltage capacitors are critical in applications such as power generation, transmission, and high-voltage direct current (HVDC) systems.

2. **Common Types**:

- **High-Voltage Ceramic Capacitors**: These capacitors are known for their reliability and are often used in high-frequency applications.

- **Oil-Filled Capacitors**: These capacitors are used in high-voltage applications due to their ability to dissipate heat effectively.

- **Glass Capacitors**: Known for their stability and reliability, glass capacitors are often used in high-voltage applications where performance is critical.

IV. Specialized Capacitors and Their Voltage Ratings

In addition to standard capacitor types, there are specialized capacitors designed for specific applications, each with unique voltage ratings.

A. Supercapacitors

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries.

1. **Definition and Characteristics**: Supercapacitors have high capacitance values and can store large amounts of energy, making them suitable for applications requiring rapid charge and discharge cycles.

2. **Voltage Ratings and Applications**: Supercapacitors typically have voltage ratings ranging from 2.5V to 3V per cell, and they are used in applications such as energy harvesting, backup power supplies, and electric vehicles.

B. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance values and stability.

1. **Definition and Characteristics**: These capacitors are made from tantalum metal and are often used in applications where space is limited.

2. **Voltage Ratings and Applications**: Tantalum capacitors typically have voltage ratings ranging from 2.5V to 50V and are commonly used in portable electronics and military applications.

C. Film Capacitors

Film capacitors are known for their reliability and low loss.

1. **Definition and Characteristics**: These capacitors use a thin plastic film as the dielectric material, providing excellent performance in various applications.

2. **Voltage Ratings and Applications**: Film capacitors can have voltage ratings ranging from a few volts to several kilovolts, making them suitable for applications in audio equipment, power supplies, and industrial machinery.

V. Applications of Capacitors Based on Voltage Ratings

Capacitors are used in a wide range of applications, and their voltage ratings play a crucial role in determining their suitability for specific tasks.

A. Consumer Electronics

In consumer electronics, capacitors are used for power supply stabilization, signal filtering, and energy storage. Common examples include capacitors in smartphones, televisions, and audio systems, where low-voltage capacitors are typically employed.

B. Industrial Applications

In industrial settings, medium-voltage capacitors are used for power factor correction, energy storage, and motor control. They help improve the efficiency of electrical systems and reduce energy costs.

C. Automotive Applications

Capacitors in automotive applications are used for various purposes, including power supply stabilization, signal filtering, and energy storage in electric and hybrid vehicles. Voltage ratings vary depending on the specific application, with both low and medium-voltage capacitors being common.

D. Renewable Energy Systems

In renewable energy systems, such as solar and wind power, capacitors are used for energy storage and power conditioning. High-voltage capacitors are often employed in these applications to handle the demands of energy transmission and storage.

VI. Safety Considerations and Best Practices

A. Importance of Adhering to Voltage Ratings

Adhering to voltage ratings is crucial for ensuring the safety and reliability of electronic systems. Exceeding voltage ratings can lead to catastrophic failures, damaging components and posing safety risks.

B. Risks of Exceeding Voltage Ratings

The risks associated with exceeding voltage ratings include dielectric breakdown, overheating, and potential fire hazards. It is essential to select capacitors with appropriate voltage ratings for specific applications to mitigate these risks.

C. Recommendations for Selecting Capacitors

When selecting capacitors, consider the following best practices:

1. **Understand the Application**: Determine the voltage requirements of the application and select capacitors accordingly.

2. **Consider Environmental Factors**: Take into account temperature, humidity, and other environmental conditions that may affect capacitor performance.

3. **Consult Manufacturer Specifications**: Always refer to manufacturer specifications and guidelines to ensure proper selection and usage.

VII. Conclusion

Understanding capacitor voltage ratings is essential for selecting the right capacitor for specific applications. From low-voltage capacitors used in consumer electronics to high-voltage capacitors employed in power transmission, each type serves a unique purpose. By adhering to voltage ratings and considering factors such as dielectric material and environmental conditions, engineers and designers can ensure the reliability and performance of their electronic systems. As technology continues to evolve, further research and learning in the field of capacitors will be crucial for developing innovative solutions in various applications.

VIII. References

1. "Capacitor Basics: Understanding Capacitor Voltage Ratings." Electronics Tutorials.

2. "The Role of Capacitors in Electronic Circuits." IEEE Spectrum.

3. "Capacitor Types and Their Applications." Electronic Design.

4. "Understanding Supercapacitors: Applications and Benefits." Journal of Energy Storage.

5. "Tantalum Capacitors: Characteristics and Applications." AVX Corporation.

This blog post provides a comprehensive overview of capacitor voltage ratings, their types, applications, and safety considerations, making it a valuable resource for anyone interested in understanding capacitors better.

2025-01-09

0

What kind of product are capacitors?

What Kind of Product Are Capacitors?

I. Introduction

Capacitors are fundamental components in the world of electronics, playing a crucial role in the functionality of various devices. Defined as passive electronic components that store and release electrical energy, capacitors are essential for managing electrical signals and power in circuits. Their importance cannot be overstated, as they are found in everything from simple household appliances to complex industrial machinery. This article will explore the basics of capacitors, their applications, specifications, manufacturing processes, and future trends, providing a comprehensive understanding of what capacitors are and why they matter.

II. The Basics of Capacitors

A. What is a Capacitor?

At its core, a capacitor is a device that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. The amount of energy a capacitor can store is determined by its capacitance, which is measured in Farads (F).

B. How Capacitors Work

The charge storage mechanism of a capacitor is relatively straightforward. When a voltage is applied, electrons accumulate on one plate, creating a negative charge, while the other plate loses electrons, resulting in a positive charge. This separation of charge creates an electric field between the plates, which can be harnessed when the capacitor is connected to a circuit. The capacitance of a capacitor is defined as the ratio of the electric charge stored on one plate to the voltage across the plates.

C. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

1. **Electrolytic Capacitors**: These are polarized capacitors that offer high capacitance values in a relatively small package. They are commonly used in power supply circuits for smoothing and filtering.

2. **Ceramic Capacitors**: Known for their stability and reliability, ceramic capacitors are often used in high-frequency applications. They are non-polarized and come in various capacitance values.

3. **Film Capacitors**: These capacitors use a thin plastic film as the dielectric. They are known for their low loss and high stability, making them suitable for audio and RF applications.

4. **Tantalum Capacitors**: Similar to electrolytic capacitors, tantalum capacitors offer high capacitance in a small size but are more stable and reliable. They are often used in compact electronic devices.

5. **Supercapacitors**: These capacitors can store a significant amount of energy and are used in applications requiring rapid charge and discharge cycles, such as in renewable energy systems and electric vehicles.

III. Capacitor Applications

Capacitors have a wide range of applications across various fields, making them indispensable in modern electronics.

A. Power Supply Smoothing

One of the primary roles of capacitors is in power supply smoothing. In electronic circuits, capacitors filter out voltage fluctuations, providing a stable output voltage. This is particularly important in power supply circuits, where capacitors help to smooth the rectified output from AC to DC, ensuring that devices receive a consistent voltage.

B. Timing Applications

Capacitors are also crucial in timing applications. In RC (resistor-capacitor) circuits, capacitors charge and discharge at predictable rates, allowing them to create time delays or oscillate. This principle is used in oscillators, timers, and various signal processing applications.

C. Signal Coupling and Decoupling

In audio and radio frequency applications, capacitors are used for signal coupling and decoupling. They allow AC signals to pass while blocking DC components, ensuring that signals are transmitted without distortion. This is vital in maintaining audio quality and signal integrity in communication systems.

D. Energy Storage

Capacitors play a significant role in energy storage, particularly in renewable energy systems and electric vehicles. Supercapacitors, in particular, can store large amounts of energy and release it quickly, making them ideal for applications that require rapid bursts of power, such as regenerative braking in electric vehicles.

E. Other Specialized Applications

Capacitors are also used in various specialized applications, including:

Medical Devices: Capacitors are used in defibrillators and other medical equipment to store and release energy safely.

Automotive Electronics: Capacitors are found in various automotive systems, including ignition systems and power management.

Consumer Electronics: From smartphones to televisions, capacitors are integral to the functioning of everyday electronic devices.

IV. Capacitor Specifications and Ratings

Understanding capacitor specifications is essential for selecting the right component for a specific application. Key specifications include:

A. Capacitance Value

The capacitance value indicates how much charge a capacitor can store. It is measured in Farads, with common values ranging from picofarads (pF) to microfarads (µF) and millifarads (mF).

B. Voltage Rating

The voltage rating specifies the maximum voltage a capacitor can handle without breaking down. Exceeding this voltage can lead to failure, so it is crucial to choose a capacitor with an appropriate voltage rating for the application.

C. Tolerance

Tolerance indicates the variation in capacitance from the stated value. It is expressed as a percentage and is important for applications requiring precise capacitance values.

D. Temperature Coefficient

The temperature coefficient describes how capacitance changes with temperature. Different applications may require capacitors with specific temperature characteristics to ensure reliable performance.

E. Equivalent Series Resistance (ESR)

ESR is a measure of the internal resistance of a capacitor, which affects its efficiency and performance in high-frequency applications. Lower ESR values are generally preferred for applications requiring rapid charge and discharge cycles.

V. Manufacturing and Quality Control

The manufacturing process of capacitors involves several steps, including material selection, assembly, and testing. Quality control measures are critical to ensure that capacitors meet industry standards and perform reliably in their intended applications.

A. Overview of the Capacitor Manufacturing Process

The manufacturing process typically begins with the selection of materials for the plates and dielectric. The plates are then coated with the dielectric material, and the assembly is completed by connecting the terminals. After assembly, capacitors undergo testing to verify their specifications and performance.

B. Quality Assurance Measures

Quality assurance measures include rigorous testing for capacitance, voltage rating, and ESR. Manufacturers often implement automated testing systems to ensure consistency and reliability in production.

C. Industry Standards and Certifications

Capacitors must meet various industry standards and certifications, such as those set by the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). Compliance with these standards ensures that capacitors are safe and reliable for use in electronic devices.

VI. Future Trends in Capacitor Technology

As technology continues to evolve, so do capacitors. Several trends are shaping the future of capacitor technology.

A. Advancements in Materials and Design

Innovations in materials and design are leading to the development of capacitors with improved performance characteristics. New dielectric materials and manufacturing techniques are enabling the production of smaller, more efficient capacitors.

B. The Rise of Supercapacitors and Their Potential

Supercapacitors are gaining popularity due to their ability to store large amounts of energy and deliver it quickly. They are being explored for use in various applications, including energy storage systems, electric vehicles, and portable electronics.

C. Environmental Considerations and Sustainability

As the demand for sustainable technologies grows, manufacturers are focusing on environmentally friendly materials and processes. This includes the development of biodegradable capacitors and recycling programs for electronic waste.

VII. Conclusion

In conclusion, capacitors are vital components in modern electronics, serving a wide range of applications from power supply smoothing to energy storage. Their ability to store and release electrical energy makes them indispensable in various devices and systems. As technology advances, capacitors will continue to evolve, with new materials and designs enhancing their performance and sustainability. Understanding the role of capacitors in electronic products is essential for anyone interested in the field of electronics, as they are foundational to the functionality of countless devices we rely on every day.

VIII. References

For further exploration of capacitors and their applications, consider the following resources:

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Capacitors: Technology and Applications" by John W. McCulloch

- Industry publications from the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC)

2025-01-09

0