Capacitors: Exploring Popular Models and Their Applications

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They are passive electrical devices that store energy in an electric field, allowing them to release that energy when needed. This article will delve into the various popular models of capacitors, their characteristics, applications, advantages, and disadvantages, as well as factors influencing their selection and future trends in capacitor technology.

II. Basic Principles of Capacitors

A. How Capacitors Work

Capacitors consist of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, causing positive and negative charges to accumulate on the respective plates. The ability of a capacitor to store charge is quantified by its capacitance, measured in farads (F).

B. Types of Capacitors Based on Construction

Capacitors can be categorized into two main types based on their construction: polarized and non-polarized capacitors. Polarized capacitors, such as electrolytic capacitors, have a specific positive and negative terminal, while non-polarized capacitors can be connected in either direction. Additionally, capacitors can be fixed, with a set capacitance value, or variable, allowing for adjustable capacitance.

III. Popular Models of Capacitors

A. Ceramic Capacitors

**Characteristics:** Ceramic capacitors are made from ceramic materials and are known for their small size and high stability. They typically have low capacitance values, ranging from picofarads (pF) to microfarads (µF).

**Applications:** These capacitors are widely used in high-frequency applications, such as RF circuits, decoupling, and filtering.

**Advantages and Disadvantages:** Ceramic capacitors are non-polarized, have low equivalent series resistance (ESR), and are cost-effective. However, they can exhibit capacitance variation with temperature and voltage, which may limit their use in precision applications.

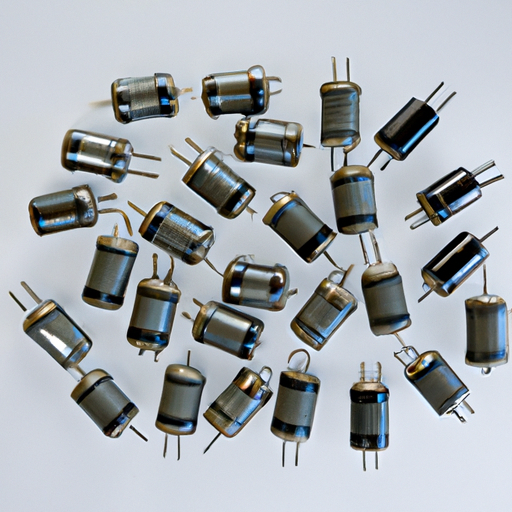

B. Electrolytic Capacitors

**Characteristics:** Electrolytic capacitors are polarized and typically have high capacitance values, ranging from microfarads to thousands of microfarads. They consist of an electrolyte and a metal oxide layer.

**Applications:** Commonly used in power supply circuits, audio equipment, and energy storage applications.

**Advantages and Disadvantages:** They offer high capacitance in a relatively small size and are cost-effective. However, they have a limited lifespan, can leak electrolyte, and are sensitive to reverse polarity.

C. Tantalum Capacitors

**Characteristics:** Tantalum capacitors are also polarized and known for their high capacitance values and stability. They use tantalum metal as the anode and a tantalum oxide layer as the dielectric.

**Applications:** Frequently used in applications requiring high reliability, such as military and aerospace electronics, as well as in portable devices.

**Advantages and Disadvantages:** Tantalum capacitors have a long lifespan, excellent frequency characteristics, and a compact size. However, they can be expensive and are sensitive to voltage surges, which can lead to catastrophic failure.

D. Film Capacitors

**Characteristics:** Film capacitors use a thin plastic film as the dielectric material. They are available in various types, including polyester, polypropylene, and polystyrene.

**Applications:** Commonly used in audio applications, timing circuits, and power electronics.

**Advantages and Disadvantages:** Film capacitors are non-polarized, have low ESR, and exhibit excellent stability and reliability. However, they tend to be larger than other types of capacitors and may have lower capacitance values.

E. Supercapacitors

**Characteristics:** Supercapacitors, also known as ultracapacitors, have extremely high capacitance values, ranging from farads to thousands of farads. They store energy through electrostatic double-layer capacitance.

**Applications:** Used in applications requiring rapid charge and discharge cycles, such as energy storage systems, regenerative braking, and backup power supplies.

**Advantages and Disadvantages:** Supercapacitors can charge and discharge quickly, have a long cycle life, and are environmentally friendly. However, they have lower energy density compared to batteries and are typically more expensive.

F. Mica Capacitors

**Characteristics:** Mica capacitors use mica as the dielectric material and are known for their high stability and precision.

**Applications:** Commonly used in RF applications, oscillators, and high-frequency circuits.

**Advantages and Disadvantages:** Mica capacitors offer excellent temperature stability and low loss. However, they can be expensive and are typically larger than other capacitor types.

G. Aluminum Capacitors

**Characteristics:** Aluminum capacitors are a type of electrolytic capacitor that uses aluminum oxide as the dielectric. They are polarized and available in various capacitance values.

**Applications:** Widely used in power supply circuits, audio equipment, and consumer electronics.

**Advantages and Disadvantages:** Aluminum capacitors are cost-effective and offer high capacitance values. However, they have a limited lifespan and can be sensitive to temperature and voltage variations.

IV. Specialized Capacitors

A. Power Capacitors

**Characteristics:** Power capacitors are designed to improve the power factor in electrical systems and are typically used in industrial applications.

**Applications:** Commonly used in power distribution systems, motor drives, and reactive power compensation.

B. RF Capacitors

**Characteristics:** RF capacitors are designed to operate at high frequencies and have low ESR.

**Applications:** Used in RF amplifiers, oscillators, and tuning circuits.

C. High Voltage Capacitors

**Characteristics:** High voltage capacitors are designed to withstand high voltage levels and are typically larger in size.

**Applications:** Commonly used in power transmission, energy storage systems, and high-voltage applications.

V. Factors Influencing Capacitor Selection

When selecting a capacitor for a specific application, several factors must be considered:

A. Capacitance Value

The required capacitance value depends on the application, with different circuits requiring different capacitance levels.

B. Voltage Rating

The voltage rating must exceed the maximum voltage the capacitor will experience in the circuit to prevent breakdown.

C. Temperature Coefficient

The temperature coefficient indicates how capacitance changes with temperature, which is crucial for applications requiring stability.

D. Size and Form Factor

The physical size and form factor of the capacitor can impact its suitability for specific applications, especially in compact designs.

E. Frequency Response

The frequency response of a capacitor affects its performance in high-frequency applications, making it essential to choose a capacitor with appropriate characteristics.

VI. Future Trends in Capacitor Technology

A. Advancements in Materials

Research is ongoing to develop new dielectric materials that can enhance capacitance, reduce size, and improve performance.

B. Miniaturization and Integration

As electronic devices become smaller, the demand for miniaturized capacitors that can be integrated into circuits is increasing.

C. Environmental Considerations

With growing concerns about environmental impact, manufacturers are exploring eco-friendly materials and production methods for capacitors.

VII. Conclusion

In summary, capacitors are essential components in modern electronics, with various models available to suit different applications. Understanding the characteristics, advantages, and disadvantages of each type of capacitor is crucial for selecting the right one for a specific application. As technology continues to advance, the role of capacitors will remain vital in shaping the future of electronic devices.

VIII. References

- Suggested Reading: "Capacitors: Principles and Applications" by John Smith

- Industry Standards and Guidelines: IEC 60384, EIA-198

- Online Resources for Further Learning: Electronics tutorials, manufacturer datasheets, and engineering forums.

By understanding the diverse range of capacitor models and their applications, engineers and hobbyists alike can make informed decisions that enhance the performance and reliability of their electronic projects.