What are the Product Features of Capacitors?

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in various applications ranging from power supply filtering to timing circuits. They are passive electrical devices that store and release electrical energy, making them essential for managing voltage and current in electronic systems. This article aims to provide a comprehensive overview of the product features of capacitors, exploring their basic principles, types, key features, and applications.

II. Basic Principles of Capacitors

A. Explanation of Capacitance

Capacitance is the ability of a capacitor to store electrical charge. It is defined as the ratio of the electric charge (Q) stored on one plate of the capacitor to the voltage (V) across the plates. The unit of capacitance is the Farad (F), which is a relatively large unit; in practice, capacitors are often rated in microfarads (µF), nanofarads (nF), or picofarads (pF).

Several factors affect capacitance:

1. **Surface Area**: The larger the surface area of the plates, the greater the capacitance.

2. **Distance**: The closer the plates are to each other, the higher the capacitance, as the electric field strength increases.

3. **Dielectric Material**: The type of insulating material (dielectric) placed between the plates influences capacitance. Different materials have different dielectric constants, which affect the capacitor's ability to store charge.

B. How Capacitors Store and Release Energy

Capacitors store energy in the form of an electric field created between their plates when a voltage is applied. During the charging cycle, electrons accumulate on one plate, creating a negative charge, while the other plate loses electrons, resulting in a positive charge. This process continues until the voltage across the capacitor equals the applied voltage.

When the capacitor discharges, the stored energy is released back into the circuit, providing a quick burst of current. This ability to store and release energy makes capacitors vital for smoothing voltage fluctuations in power supplies, filtering signals, and providing timing functions in circuits.

III. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications. Here are some of the most common types:

A. Ceramic Capacitors

Ceramic capacitors are made from ceramic materials and are widely used due to their small size and low cost. They are available in various capacitance values and voltage ratings.

**Advantages**:

- High stability and reliability

- Low equivalent series resistance (ESR)

**Disadvantages**:

- Limited capacitance values

- Voltage coefficient can affect performance

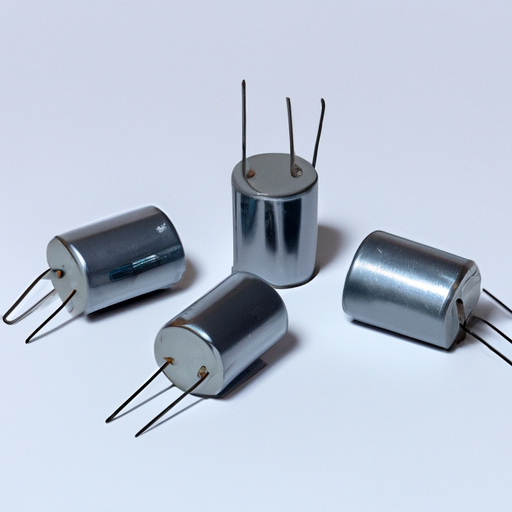

B. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that use an electrolyte to achieve a larger capacitance value in a smaller package. They are commonly used in power supply applications.

**Advantages**:

- High capacitance values

- Cost-effective for bulk capacitance

**Disadvantages**:

- Limited voltage ratings

- Shorter lifespan compared to other types

C. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material. They are known for their stability and low loss characteristics.

**Advantages**:

- Excellent temperature stability

- Low ESR and ESL (equivalent series inductance)

**Disadvantages**:

- Larger size compared to ceramic and electrolytic capacitors

- Generally lower capacitance values

D. Tantalum Capacitors

Tantalum capacitors are another type of electrolytic capacitor, known for their high capacitance and small size. They are often used in applications where space is limited.

**Advantages**:

- High capacitance in a small package

- Stable performance over a wide temperature range

**Disadvantages**:

- Higher cost

- Risk of failure if subjected to over-voltage conditions

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, have extremely high capacitance values and are used for energy storage applications. They can charge and discharge rapidly, making them suitable for applications requiring quick bursts of energy.

**Advantages**:

- Very high capacitance values

- Long cycle life

**Disadvantages**:

- Lower voltage ratings

- Higher self-discharge rates

IV. Key Product Features of Capacitors

When selecting capacitors for specific applications, several key features must be considered:

A. Capacitance Value

The capacitance value is one of the most critical specifications of a capacitor. It determines how much charge the capacitor can store and is essential for circuit design. Capacitors are available in a wide range of values, from picofarads to farads, allowing designers to choose the appropriate capacitor for their needs.

B. Voltage Rating

The voltage rating indicates the maximum voltage a capacitor can handle without breaking down. Exceeding this rating can lead to catastrophic failure. It is crucial to select a capacitor with a voltage rating higher than the maximum voltage expected in the application to ensure safety and reliability.

C. Tolerance

Tolerance refers to the allowable deviation from the nominal capacitance value. Capacitors are available with different tolerance levels, which can significantly impact precision applications. For example, a capacitor with a tolerance of ±5% can vary from its stated value by 5%, while one with ±1% offers greater precision.

D. Temperature Coefficient

The temperature coefficient indicates how the capacitance value changes with temperature. Capacitors with a low temperature coefficient are preferred in applications where temperature variations are expected, as they maintain stable performance across a range of temperatures.

E. Equivalent Series Resistance (ESR)

ESR is a measure of the internal resistance of a capacitor, which affects its efficiency and heat generation during operation. Low ESR is desirable in applications where high-frequency performance and efficiency are critical, such as in power supply circuits.

F. Lifetime and Reliability

The lifespan of a capacitor can vary significantly based on its type, operating conditions, and environmental factors. Factors such as temperature, voltage, and ripple current can affect a capacitor's reliability and longevity. In critical applications, selecting capacitors with a proven track record of reliability is essential.

V. Applications of Capacitors

Capacitors are used in a wide range of applications, including:

A. Power Supply Filtering

Capacitors are commonly used in power supply circuits to filter out voltage fluctuations and provide a stable output. They smooth the rectified voltage in power supplies, ensuring that electronic devices receive a consistent voltage.

B. Signal Coupling and Decoupling

In audio and radio frequency applications, capacitors are used to couple and decouple signals. They allow AC signals to pass while blocking DC components, ensuring that only the desired signals are transmitted.

C. Timing Circuits

Capacitors are essential in timing circuits, where they work in conjunction with resistors to create time delays. This is commonly seen in applications such as oscillators and timers.

D. Energy Storage Systems

Supercapacitors are increasingly used in energy storage systems, providing quick bursts of energy for applications such as regenerative braking in electric vehicles and backup power for electronic devices.

E. Motor Starters and Drives

Capacitors are used in motor starter circuits to provide the initial boost of energy needed to start electric motors. They are also used in variable frequency drives to improve motor efficiency.

VI. Conclusion

Understanding the product features of capacitors is essential for anyone involved in electronics, from hobbyists to professional engineers. Capacitors play a vital role in a wide range of applications, and selecting the right type and specifications can significantly impact the performance and reliability of electronic circuits.

As technology continues to evolve, so too will capacitor technology, with trends such as miniaturization, increased capacitance values, and improved materials leading the way. For those interested in electronics, further exploration and study of capacitors will provide valuable insights into their critical role in modern technology.