What Product Types are Included in Chip Adjustable Resistors?

I. Introduction

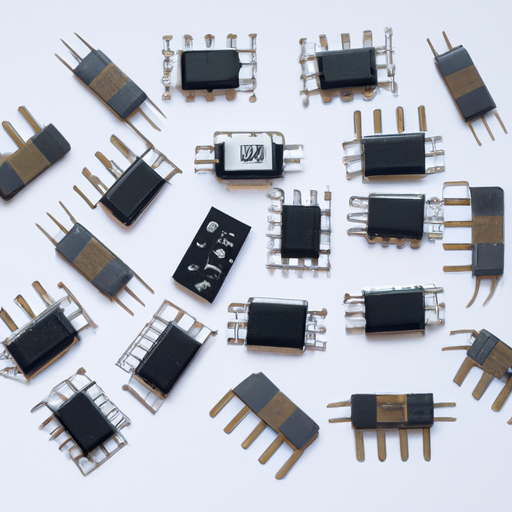

In the realm of electronics, resistors play a pivotal role in controlling current flow and voltage levels within circuits. Among the various types of resistors, chip adjustable resistors stand out due to their versatility and precision. These components allow engineers and designers to fine-tune circuit performance, making them essential in a wide array of applications. This article aims to explore the different product types included in chip adjustable resistors, their functions, applications, and the advantages they offer in modern electronic designs.

II. Understanding Chip Adjustable Resistors

A. Explanation of Resistors and Their Function in Circuits

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are characterized by their resistance value, measured in ohms (Ω). By controlling current flow, resistors help to protect sensitive components, divide voltages, and set bias points in amplifiers.

B. Distinction Between Fixed and Adjustable Resistors

While fixed resistors have a set resistance value, adjustable resistors allow for variable resistance. This adjustability is crucial in applications where precise control over current and voltage is necessary. Adjustable resistors can be manually tuned or electronically controlled, depending on the type.

C. Overview of Chip Technology in Resistors

Chip technology has revolutionized the design and manufacturing of resistors, allowing for smaller, more efficient components. Chip adjustable resistors are typically surface-mounted devices (SMDs), which facilitate compact circuit designs and enhance performance in high-density applications.

III. Types of Chip Adjustable Resistors

A. Trimming Potentiometers

1. Definition and Function

Trimming potentiometers are a type of adjustable resistor used primarily for fine-tuning circuit parameters. They consist of a resistive element and a wiper that moves along the element to adjust resistance.

2. Applications in Circuit Calibration

These potentiometers are commonly employed in calibration processes, allowing engineers to make precise adjustments to circuit performance. They are often found in audio equipment, instrumentation, and other sensitive electronic devices.

3. Variants and Specifications

Trimming potentiometers come in various forms, including single-turn and multi-turn designs, each suited for different calibration needs. Specifications such as resistance range, tolerance, and power rating are critical when selecting the appropriate trimming potentiometer for a specific application.

B. Digital Potentiometers

1. Definition and Function

Digital potentiometers are electronically controlled resistors that can be adjusted using digital signals. They replace traditional mechanical potentiometers, offering enhanced precision and reliability.

2. Advantages Over Traditional Potentiometers

Digital potentiometers provide several advantages, including non-volatility, resistance to wear, and the ability to interface directly with microcontrollers. This makes them ideal for applications requiring frequent adjustments or remote control.

3. Common Applications in Digital Circuits

These components are widely used in digital signal processing, audio control, and programmable gain amplifiers, where precise resistance values are crucial for optimal performance.

C. Variable Resistors (Rheostats)

1. Definition and Function

Variable resistors, or rheostats, are adjustable resistors that can handle higher power levels. They are typically used to control current in larger circuits.

2. Differences from Potentiometers

Unlike potentiometers, which have three terminals, rheostats usually have two terminals and are designed for applications where the entire resistance range is utilized.

3. Use Cases in Power Applications

Rheostats are commonly found in applications such as motor speed control, lighting dimmers, and heating elements, where significant power handling is required.

D. Programmable Resistors

1. Definition and Function

Programmable resistors are adjustable resistors that can be set to specific resistance values through programming. They are often integrated with microcontrollers for automated control.

2. Integration with Microcontrollers

These resistors can be programmed to change resistance based on input signals, making them suitable for dynamic applications where resistance needs to be adjusted in real-time.

3. Applications in Automated Systems

Programmable resistors are used in automated systems, such as robotics and smart home devices, where adaptability and precision are essential.

E. Multi-turn Potentiometers

1. Definition and Function

Multi-turn potentiometers allow for more precise adjustments than single-turn potentiometers, as they can be turned multiple times to achieve the desired resistance.

2. Precision Applications

These potentiometers are ideal for applications requiring high precision, such as calibration instruments and sensitive measurement devices.

3. Comparison with Single-turn Potentiometers

While single-turn potentiometers are easier to adjust quickly, multi-turn potentiometers provide finer control, making them suitable for applications where accuracy is paramount.

F. Tapered Potentiometers

1. Definition and Function

Tapered potentiometers have a resistive element designed to provide a specific change in resistance over the rotation of the wiper. They can be linear or logarithmic in taper.

2. Explanation of Linear vs. Logarithmic Taper

Linear taper potentiometers provide a uniform change in resistance, while logarithmic taper potentiometers change resistance in a non-linear fashion, which is often more suitable for audio applications.

3. Applications in Audio and Signal Processing

Tapered potentiometers are commonly used in audio equipment, where logarithmic taper is preferred for volume controls, providing a more natural response to human hearing.

IV. Key Features and Specifications

A. Resistance Range and Tolerance

The resistance range of chip adjustable resistors varies widely, and tolerance levels indicate how much the actual resistance can deviate from the specified value. Selecting the right range and tolerance is crucial for circuit performance.

B. Power Rating and Thermal Characteristics

Power rating indicates the maximum power the resistor can handle without overheating. Thermal characteristics are also important, as they affect the resistor's performance under varying temperature conditions.

C. Size and Footprint Considerations

Chip adjustable resistors come in various sizes, and their footprint is a critical factor in circuit design, especially in compact electronic devices.

D. Environmental Ratings and Reliability

Environmental ratings indicate the resistor's ability to withstand harsh conditions, such as humidity and temperature extremes. Reliability is essential for ensuring long-term performance in critical applications.

V. Applications of Chip Adjustable Resistors

A. Consumer Electronics

Chip adjustable resistors are widely used in consumer electronics, including smartphones, televisions, and audio systems, where precise control over performance is essential.

B. Automotive Systems

In automotive applications, these resistors are used for sensor calibration, control systems, and infotainment systems, enhancing vehicle performance and user experience.

C. Industrial Automation

In industrial settings, chip adjustable resistors are employed in automation systems, robotics, and control panels, where reliability and precision are paramount.

D. Telecommunications

Telecommunications equipment relies on adjustable resistors for signal processing and transmission, ensuring optimal performance in communication systems.

E. Medical Devices

In medical devices, chip adjustable resistors are crucial for calibration and control, ensuring accurate readings and reliable operation in critical healthcare applications.

VI. Advantages of Using Chip Adjustable Resistors

A. Space-saving Design

The compact nature of chip adjustable resistors allows for more efficient use of space in circuit designs, enabling the development of smaller and more portable electronic devices.

B. Enhanced Precision and Control

These resistors provide precise control over resistance values, allowing for fine-tuning of circuit performance and improved overall functionality.

C. Improved Reliability and Performance

Chip adjustable resistors are designed for durability and reliability, ensuring consistent performance even in demanding environments.

D. Cost-effectiveness in Mass Production

The integration of chip technology in adjustable resistors allows for cost-effective mass production, making them accessible for a wide range of applications.

VII. Challenges and Considerations

A. Selection Criteria for Specific Applications

Choosing the right type of chip adjustable resistor requires careful consideration of factors such as resistance range, power rating, and application requirements.

B. Potential Limitations in Performance

While chip adjustable resistors offer many advantages, they may have limitations in terms of power handling and environmental resistance compared to traditional resistors.

C. Future Trends in Adjustable Resistor Technology

As technology advances, we can expect to see further innovations in adjustable resistor design, including enhanced integration with digital systems and improved performance characteristics.

VIII. Conclusion

Chip adjustable resistors are integral components in modern electronic circuits, offering a range of product types that cater to various applications. From trimming potentiometers to digital potentiometers and programmable resistors, each type serves a unique purpose in enhancing circuit performance. As technology continues to evolve, the importance of these components will only grow, paving the way for more sophisticated and efficient electronic designs.

IX. References

For further exploration of chip adjustable resistors and their applications, consider the following resources:

- "Electronic Components: A Complete Reference for Engineers and Technicians" by John Doe

- "Understanding Resistors: A Guide for Engineers" by Jane Smith

- Industry standards and guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

By understanding the various types of chip adjustable resistors and their applications, engineers can make informed decisions that enhance the performance and reliability of their electronic designs.