What are the Popular Resistor Parameter Product Models?

I. Introduction

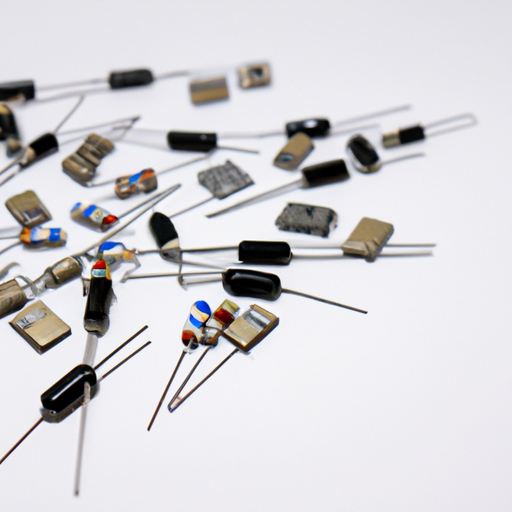

In the world of electronics, resistors play a crucial role in circuit design and functionality. Resistor parameter product models are essential tools that help engineers and designers select the right resistors for their applications. These models provide a framework for understanding the various parameters that define a resistor's performance, ensuring that the components used in electronic devices meet the required specifications. This article will explore the popular resistor parameter product models, their significance, and how they influence the design and manufacturing of electronic circuits.

II. Understanding Resistor Parameters

A. Key Parameters of Resistors

To appreciate the importance of resistor parameter product models, it is essential to understand the key parameters that define resistors:

1. **Resistance Value**: This is the primary characteristic of a resistor, measured in ohms (Ω). It determines how much current will flow through the resistor when a voltage is applied.

2. **Tolerance**: Tolerance indicates the precision of the resistor's resistance value. It is expressed as a percentage and shows how much the actual resistance can vary from the stated value. For example, a resistor with a tolerance of ±5% can have a resistance value that is 5% higher or lower than its nominal value.

3. **Temperature Coefficient**: This parameter describes how the resistance of a resistor changes with temperature. It is typically expressed in parts per million per degree Celsius (ppm/°C). A low temperature coefficient is desirable for applications requiring stable performance across varying temperatures.

4. **Power Rating**: The power rating indicates the maximum amount of power (in watts) that a resistor can dissipate without being damaged. Exceeding this rating can lead to overheating and failure.

5. **Voltage Rating**: This parameter specifies the maximum voltage that can be applied across the resistor without causing breakdown or failure. It is crucial for ensuring that the resistor operates safely within its limits.

B. The Role of Each Parameter in Circuit Design

Each of these parameters plays a vital role in circuit design. For instance, selecting a resistor with the appropriate resistance value is fundamental to achieving the desired current flow. Tolerance affects the accuracy of the circuit, while the temperature coefficient ensures that the resistor performs reliably under varying environmental conditions. Power and voltage ratings are critical for preventing component failure and ensuring the longevity of the circuit.

III. Popular Resistor Parameter Product Models

A. Overview of Resistor Product Models

Resistor parameter product models serve as guidelines for selecting resistors based on their parameters. These models help engineers and designers make informed decisions during the design and manufacturing processes.

B. Commonly Used Models

1. **E12 and E24 Series**:

- **Explanation of the E-Series**: The E12 and E24 series are standard sets of preferred numbers for resistor values. The E12 series consists of 12 values per decade, while the E24 series includes 24 values. These series are designed to provide a range of resistance values that are easy to remember and use.

- **Applications and Benefits**: These series are widely used in consumer electronics and general applications due to their availability and cost-effectiveness. They simplify the selection process for designers by providing a standardized set of values.

2. **E96 and E192 Series**:

- **High Precision Resistors**: The E96 and E192 series offer higher precision with 96 and 192 values per decade, respectively. These series are essential for applications requiring tight tolerances and high accuracy.

- **Applications in High-End Electronics**: These models are commonly used in precision instruments, medical devices, and high-end audio equipment, where performance and reliability are paramount.

3. **Power Resistor Models**:

- **Wirewound Resistors**: These resistors are made by winding a metal wire around a ceramic or plastic core. They are known for their high power ratings and stability, making them suitable for applications that require significant power dissipation.

- **Thick Film Resistors**: Thick film resistors are created by printing a resistive material onto a substrate. They are widely used in surface-mount technology (SMT) and offer good performance at a lower cost.

- **Thin Film Resistors**: Thin film resistors are made by depositing a thin layer of resistive material on a substrate. They provide high precision and stability, making them ideal for applications in telecommunications and instrumentation.

4. **Specialty Resistor Models**:

- **Thermistors**: These temperature-sensitive resistors change resistance with temperature variations. They are commonly used in temperature sensing and compensation applications.

- **Photoresistors**: Also known as light-dependent resistors (LDRs), photoresistors change resistance based on light intensity. They are used in light-sensing applications, such as automatic lighting systems.

- **Varistors**: Varistors are voltage-dependent resistors that protect circuits from voltage spikes. They are commonly used in surge protection devices.

IV. Factors Influencing the Choice of Resistor Models

A. Application Requirements

1. **Circuit Complexity**: The complexity of the circuit often dictates the type of resistors needed. Simple circuits may only require standard E12 or E24 resistors, while complex circuits may necessitate high-precision E96 or E192 resistors.

2. **Environmental Conditions**: Resistors must be chosen based on the environmental conditions they will operate in. For example, high-temperature applications may require resistors with low temperature coefficients.

B. Performance Characteristics

1. **Stability and Reliability**: The stability of a resistor's performance over time and under varying conditions is crucial for ensuring the reliability of the entire circuit.

2. **Cost Considerations**: Budget constraints often influence the choice of resistor models. While high-precision resistors offer better performance, they may also come at a higher cost.

C. Manufacturer Specifications

1. **Quality Assurance**: Manufacturers provide specifications and quality assurance for their products. It is essential to choose resistors from reputable manufacturers to ensure reliability and performance.

2. **Availability of Components**: The availability of specific resistor models can also influence the selection process. Designers often prefer components that are readily available to avoid delays in production.

V. Case Studies of Resistor Parameter Product Models in Use

A. Consumer Electronics

In consumer electronics, resistors are used in various applications, from smartphones to home appliances. For instance, in smartphones, E12 and E24 series resistors are commonly used for signal processing and power management, ensuring efficient operation and reliability.

B. Automotive Applications

In electric vehicles, resistors play a critical role in battery management systems, motor control, and safety features. High-precision E96 resistors are often employed in these applications to ensure accurate measurements and control.

C. Industrial Applications

In automation and control systems, resistors are used in sensors, actuators, and control circuits. Specialty resistors, such as thermistors and photoresistors, are commonly used for temperature and light sensing, contributing to the efficiency and reliability of industrial processes.

VI. Future Trends in Resistor Parameter Product Models

A. Advances in Material Science

The development of new materials is leading to the creation of resistors with improved performance characteristics, such as higher power ratings and lower temperature coefficients.

B. Miniaturization and Integration

As electronic devices continue to shrink in size, there is a growing demand for smaller and more integrated resistor models. This trend is driving innovation in resistor design and manufacturing.

C. Smart Resistors and IoT Applications

With the rise of the Internet of Things (IoT), there is an increasing need for smart resistors that can communicate and adapt to changing conditions. These advanced resistors will play a vital role in the development of smart devices and systems.

VII. Conclusion

Resistor parameter product models are essential tools for engineers and designers in the electronics industry. Understanding the key parameters and popular models helps ensure that the right resistors are selected for various applications. As technology continues to evolve, staying informed about the latest trends and advancements in resistor design will be crucial for developing reliable and efficient electronic devices. Whether you are a seasoned engineer or a newcomer to the field, further research and learning about resistor parameter product models will enhance your understanding and application of these vital components.

VIII. References

A. Suggested Reading and Resources

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Electronic Components: A Complete Reference for Engineers and Technicians" by John L. Hennessy

B. Industry Standards and Guidelines

- IEC 60115: Resistors for use in electronic equipment

- EIA-96: Preferred Number Series for Resistors