What are the Product Features of Power Wirewound Resistors?

I. Introduction

Power wirewound resistors are essential components in electronic circuits, playing a critical role in controlling current flow and voltage levels. These resistors are designed to handle high power levels, making them suitable for a variety of applications, from industrial machinery to consumer electronics. In this article, we will explore the construction, electrical characteristics, performance features, applications, advantages, and limitations of power wirewound resistors, providing a comprehensive understanding of their significance in modern electronics.

II. Construction of Power Wirewound Resistors

A. Materials Used

The construction of power wirewound resistors involves specific materials that contribute to their performance and durability.

1. **Wire Materials**: The wire used in these resistors is typically made from alloys such as nickel-chromium or copper-nickel. These materials are chosen for their excellent electrical resistance properties and ability to withstand high temperatures.

2. **Core Materials**: The core of the resistor is often made from ceramic or fiberglass. These materials provide insulation and support, ensuring that the resistor can handle the heat generated during operation without degrading.

B. Manufacturing Process

The manufacturing process of power wirewound resistors involves several key techniques:

1. **Winding Techniques**: The wire is wound around a core in a precise manner to achieve the desired resistance value. The winding can be done in various configurations, such as helical or spiral, depending on the design requirements.

2. **Insulation Methods**: After winding, the resistor is insulated to prevent short circuits and ensure safety. This can involve coating the resistor with a layer of insulating material or using heat-shrink tubing.

C. Physical Characteristics

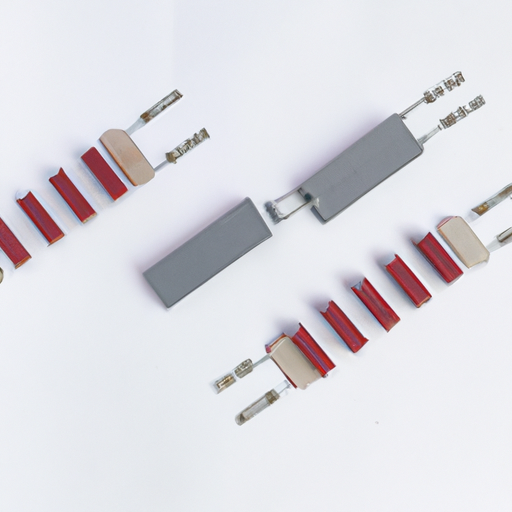

Power wirewound resistors come in various sizes and shapes, which can affect their performance and application:

1. **Size and Shape Variations**: These resistors can be found in cylindrical, rectangular, or custom shapes, allowing for flexibility in design and integration into different electronic systems.

2. **Heat Dissipation Features**: Effective heat dissipation is crucial for maintaining performance. Many power wirewound resistors are designed with features such as fins or heat sinks to enhance thermal management.

III. Electrical Characteristics

A. Resistance Values

Power wirewound resistors are available in a wide range of resistance values, making them versatile for different applications:

1. **Range of Resistance Values Available**: They can be manufactured to provide resistance values from a few ohms to several megaohms, catering to various circuit requirements.

2. **Tolerance Levels**: The tolerance of these resistors typically ranges from 1% to 5%, indicating the precision with which they can maintain their resistance value under different conditions.

B. Power Rating

The power rating of a resistor is a critical specification that indicates how much power it can handle without overheating:

1. **Definition and Significance**: The power rating is usually expressed in watts (W) and is determined by the resistor's construction and materials. It is essential to select a resistor with an appropriate power rating for the application to prevent failure.

2. **Comparison with Other Resistor Types**: Power wirewound resistors generally have higher power ratings compared to carbon film or metal film resistors, making them suitable for high-power applications.

C. Temperature Coefficient

The temperature coefficient of a resistor indicates how its resistance changes with temperature:

1. **Explanation of Temperature Coefficient**: This is usually expressed in parts per million per degree Celsius (ppm/°C). A lower temperature coefficient means better stability over a range of temperatures.

2. **Impact on Performance**: A resistor with a low temperature coefficient will maintain its resistance value more consistently, which is crucial in precision applications.

IV. Performance Features

A. Stability and Reliability

Power wirewound resistors are known for their stability and reliability:

1. **Long-term Performance Under Load**: These resistors can maintain their performance over extended periods, even under continuous load conditions.

2. **Resistance to Environmental Factors**: They are often designed to withstand harsh environmental conditions, including humidity, temperature fluctuations, and mechanical stress.

B. Noise Characteristics

Noise can significantly affect the performance of electronic circuits:

1. **Types of Noise**: Power wirewound resistors exhibit low thermal noise, making them suitable for applications where signal integrity is critical.

2. **Comparison with Other Resistor Types**: Compared to carbon resistors, wirewound resistors produce less noise, making them preferable in high-fidelity audio and sensitive measurement applications.

C. Frequency Response

The frequency response of a resistor indicates how it behaves at different frequencies:

1. **Behavior at Different Frequencies**: Power wirewound resistors can perform well at high frequencies, although they may exhibit some inductance due to their construction.

2. **Applications in High-Frequency Circuits**: Their ability to handle high frequencies makes them suitable for RF applications and other high-speed electronic circuits.

V. Applications of Power Wirewound Resistors

Power wirewound resistors are utilized in a wide range of applications across various industries:

A. Industrial Applications

1. **Power Supplies**: They are commonly used in power supply circuits to manage voltage and current levels effectively.

2. **Motor Control Systems**: In motor control applications, these resistors help regulate current flow, ensuring smooth operation.

B. Consumer Electronics

1. **Audio Equipment**: High-fidelity audio systems often incorporate power wirewound resistors to maintain signal integrity and minimize noise.

2. **Home Appliances**: These resistors are used in various home appliances, such as washing machines and microwaves, to control power levels.

C. Automotive Applications

1. **Engine Control Units**: Power wirewound resistors are critical in automotive electronics, particularly in engine control units, where precise resistance values are necessary for optimal performance.

2. **Electric Vehicles**: As electric vehicles become more prevalent, the demand for reliable power wirewound resistors in battery management systems and motor controllers is increasing.

VI. Advantages of Power Wirewound Resistors

Power wirewound resistors offer several advantages that make them a preferred choice in many applications:

A. High Power Handling Capability

These resistors can handle significant power levels, making them suitable for high-demand applications.

B. Excellent Thermal Stability

Their ability to maintain performance under varying temperature conditions ensures reliability in critical applications.

C. Low Inductance and Capacitance

Power wirewound resistors typically exhibit low inductance and capacitance, which is beneficial in high-frequency applications.

D. Customizability for Specific Applications

Manufacturers can customize power wirewound resistors to meet specific requirements, including resistance values, power ratings, and physical dimensions.

VII. Limitations of Power Wirewound Resistors

Despite their advantages, power wirewound resistors have some limitations:

A. Size and Weight Considerations

These resistors can be larger and heavier than other types, which may be a drawback in compact electronic designs.

B. Cost Factors Compared to Other Resistor Types

Power wirewound resistors are generally more expensive than carbon or metal film resistors, which can impact budget-sensitive projects.

C. Limited Resistance Range in Some Cases

While they offer a wide range of resistance values, there may be limitations in specific applications where very high or very low resistance values are required.

VIII. Conclusion

In summary, power wirewound resistors are vital components in electronic circuits, offering high power handling capabilities, excellent thermal stability, and low noise characteristics. Their construction, electrical characteristics, and performance features make them suitable for a wide range of applications, from industrial machinery to consumer electronics and automotive systems. However, it is essential to consider their limitations, such as size, weight, and cost, when selecting the right resistor for a specific application. As technology advances, we can expect further innovations in wirewound resistor technology, enhancing their performance and expanding their applications in the future.

IX. References

For further reading and resources on power wirewound resistors, consider exploring industry standards and guidelines, as well as technical articles and manufacturer specifications. Understanding these resources can provide deeper insights into the selection and application of resistors in electronic design.