Market Policies for Resistor Boxes

I. Introduction

A. Definition of Resistor Boxes

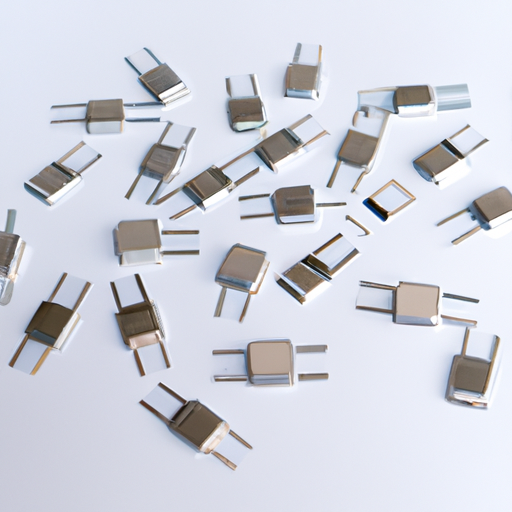

Resistor boxes, also known as resistor networks or resistor packs, are essential components in electronic circuits. They consist of multiple resistors housed in a single package, allowing for easy integration into various applications. These boxes can be fixed or variable, providing flexibility in resistance values for different electronic designs.

B. Importance of Resistor Boxes in Electronics

In the realm of electronics, resistor boxes play a crucial role in controlling current flow, dividing voltages, and protecting sensitive components from excessive current. Their versatility makes them indispensable in consumer electronics, industrial machinery, automotive systems, and more. As the electronics industry continues to expand, the demand for reliable and efficient resistor boxes is on the rise.

C. Overview of Market Policies

Understanding the market policies surrounding resistor boxes is vital for manufacturers, distributors, and consumers alike. These policies encompass regulatory frameworks, pricing strategies, distribution channels, and marketing approaches that shape the landscape of the resistor box market.

II. Market Overview

A. Global Market Trends

1. Growth of the Electronics Industry

The global electronics industry has witnessed significant growth over the past decade, driven by advancements in technology and increasing consumer demand. This growth has led to a corresponding rise in the demand for resistor boxes, as they are integral to the functioning of various electronic devices.

2. Demand for Resistor Boxes

As electronic devices become more complex, the need for precise and reliable resistor solutions has intensified. Industries such as telecommunications, automotive, and consumer electronics are particularly reliant on high-quality resistor boxes to ensure optimal performance and safety.

B. Key Players in the Market

1. Major Manufacturers

The resistor box market is characterized by several key players, including established manufacturers like Vishay Intertechnology, Yageo Corporation, and Panasonic. These companies have a strong presence in the market, offering a wide range of resistor products to meet diverse customer needs.

2. Emerging Companies

In addition to major manufacturers, emerging companies are also making their mark in the resistor box market. Startups and smaller firms are innovating with new technologies and materials, contributing to a dynamic and competitive landscape.

C. Market Segmentation

1. By Type (Fixed, Variable, etc.)

The resistor box market can be segmented by type, with fixed and variable resistor boxes being the primary categories. Fixed resistor boxes offer predetermined resistance values, while variable resistor boxes allow users to adjust resistance as needed, catering to different applications.

2. By Application (Consumer Electronics, Industrial, Automotive, etc.)

Market segmentation by application reveals the diverse uses of resistor boxes. Consumer electronics, industrial equipment, and automotive systems are among the leading sectors driving demand, each requiring specific resistor characteristics to meet performance standards.

III. Regulatory Framework

A. International Standards

1. IEC (International Electrotechnical Commission)

The IEC sets international standards for electrical and electronic devices, including resistor boxes. Compliance with IEC standards ensures that products meet safety and performance criteria, facilitating global trade.

2. ISO (International Organization for Standardization)

ISO standards also play a crucial role in the resistor box market, focusing on quality management and product consistency. Adhering to ISO standards helps manufacturers enhance their reputation and build trust with customers.

B. National Regulations

1. FCC (Federal Communications Commission) in the USA

In the United States, the FCC regulates electronic devices to minimize interference with communication systems. Resistor boxes used in communication equipment must comply with FCC regulations to ensure proper functionality and safety.

2. CE Marking in Europe

In Europe, CE marking indicates that a product meets safety and environmental requirements. Resistor boxes sold in the European market must bear the CE mark, demonstrating compliance with relevant directives.

C. Compliance and Certification Processes

Manufacturers must navigate complex compliance and certification processes to ensure their resistor boxes meet regulatory standards. This often involves rigorous testing and documentation, which can be time-consuming but is essential for market entry.

IV. Pricing Strategies

A. Cost-Based Pricing

1. Factors Influencing Production Costs

Production costs for resistor boxes are influenced by various factors, including raw material prices, manufacturing processes, and labor costs. Understanding these factors is crucial for manufacturers to set competitive prices.

2. Impact on Retail Pricing

Cost-based pricing strategies directly impact retail pricing. Manufacturers must balance production costs with market demand to ensure profitability while remaining attractive to consumers.

B. Value-Based Pricing

1. Perceived Value to Customers

Value-based pricing focuses on the perceived value of resistor boxes to customers. Manufacturers must understand customer needs and preferences to set prices that reflect the value provided.

2. Competitive Analysis

Conducting competitive analysis is essential for value-based pricing. By evaluating competitors' pricing strategies, manufacturers can position their products effectively in the market.

C. Discounts and Promotions

1. Seasonal Sales

Seasonal sales and promotions can drive demand for resistor boxes, allowing manufacturers to clear inventory and attract new customers. Strategic timing and marketing are key to successful promotions.

2. Bulk Purchase Discounts

Offering bulk purchase discounts can incentivize larger orders from distributors and retailers, increasing overall sales volume and fostering long-term relationships with customers.

V. Distribution Channels

A. Direct Sales

1. Manufacturer to Consumer

Direct sales channels allow manufacturers to sell resistor boxes directly to consumers, enhancing profit margins and fostering customer relationships. This approach is increasingly popular with the rise of e-commerce.

2. Online Sales Platforms

Online sales platforms provide manufacturers with a broader reach, enabling them to tap into global markets. E-commerce has transformed the distribution landscape, making it easier for consumers to access resistor boxes.

B. Indirect Sales

1. Distributors and Wholesalers

Distributors and wholesalers play a vital role in the resistor box market, acting as intermediaries between manufacturers and retailers. They help streamline the supply chain and ensure product availability.

2. Retail Partnerships

Establishing retail partnerships can enhance market presence and accessibility for resistor boxes. Collaborating with established retailers allows manufacturers to leverage existing customer bases.

C. E-commerce Trends

1. Growth of Online Marketplaces

The growth of online marketplaces has revolutionized the way resistor boxes are sold. Consumers increasingly prefer the convenience of online shopping, prompting manufacturers to invest in digital sales strategies.

2. Impact of Digital Marketing

Digital marketing plays a crucial role in promoting resistor boxes in the online space. Manufacturers must utilize social media, search engine optimization, and targeted advertising to reach potential customers effectively.

VI. Marketing Strategies

A. Branding and Positioning

1. Importance of Brand Recognition

Brand recognition is essential in the resistor box market, as consumers often prefer established brands known for quality and reliability. Manufacturers must invest in branding efforts to build a strong market presence.

2. Differentiation from Competitors

Differentiating resistor boxes from competitors is crucial for attracting customers. Manufacturers can achieve this through unique product features, superior quality, or exceptional customer service.

B. Advertising and Promotion

1. Traditional vs. Digital Marketing

A balanced approach to advertising, combining traditional and digital marketing strategies, can maximize reach and engagement. Manufacturers should tailor their marketing efforts to target specific customer segments effectively.

2. Trade Shows and Industry Events

Participating in trade shows and industry events provides manufacturers with opportunities to showcase their resistor boxes, network with potential customers, and stay updated on market trends.

C. Customer Engagement

1. Feedback Mechanisms

Implementing feedback mechanisms allows manufacturers to gather insights from customers, helping them improve product offerings and address any concerns. Engaging with customers fosters loyalty and trust.

2. Building Customer Loyalty

Building customer loyalty is essential for long-term success in the resistor box market. Manufacturers can achieve this through exceptional customer service, loyalty programs, and consistent product quality.

VII. Challenges and Opportunities

A. Market Challenges

1. Supply Chain Disruptions

Supply chain disruptions, exacerbated by global events such as pandemics or geopolitical tensions, pose significant challenges for the resistor box market. Manufacturers must develop strategies to mitigate these risks and ensure consistent product availability.

2. Technological Advancements

Rapid technological advancements can render existing resistor box designs obsolete. Manufacturers must stay ahead of the curve by investing in research and development to innovate and adapt to changing market demands.

B. Opportunities for Growth

1. Emerging Markets

Emerging markets present significant growth opportunities for resistor box manufacturers. As developing countries invest in infrastructure and technology, the demand for electronic components, including resistor boxes, is expected to rise.

2. Innovations in Resistor Technology

Innovations in resistor technology, such as the development of more efficient materials and designs, can enhance product performance and open new market segments. Manufacturers should prioritize research and development to capitalize on these opportunities.

VIII. Future Outlook

A. Predictions for Market Growth

The resistor box market is poised for continued growth, driven by the expanding electronics industry and increasing demand for reliable components. Market analysts predict a steady rise in sales over the next several years.

B. Evolving Consumer Preferences

As consumer preferences evolve, manufacturers must adapt their product offerings to meet changing demands. This includes a focus on sustainability, energy efficiency, and advanced features that enhance performance.

C. Technological Innovations Impacting the Market

Technological innovations, such as the integration of smart technologies and IoT capabilities, are expected to impact the resistor box market significantly. Manufacturers that embrace these trends will be well-positioned for future success.

IX. Conclusion

A. Summary of Key Points

In summary, the market policies for resistor boxes encompass a wide range of factors, including regulatory frameworks, pricing strategies, distribution channels, and marketing approaches. Understanding these elements is crucial for stakeholders in the resistor box market.

B. Importance of Adapting to Market Policies

As the electronics industry continues to evolve, manufacturers and distributors must adapt to changing market policies to remain competitive. Staying informed about regulations, pricing trends, and consumer preferences is essential for success.

C. Final Thoughts on the Future of Resistor Boxes

The future of resistor boxes looks promising, with opportunities for growth and innovation on the horizon. By embracing technological advancements and responding to market demands, manufacturers can thrive in this dynamic industry. As the world becomes increasingly reliant on electronic devices, the importance of high-quality resistor boxes will only continue to grow.