The Production Process of Mainstream Glass Glaze Resistors

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, glass glaze resistors are notable for their durability, stability, and ability to withstand high temperatures. These components are essential in a wide range of applications, from consumer electronics to industrial machinery. This blog post will delve into the production process of mainstream glass glaze resistors, exploring the raw materials, fabrication techniques, firing processes, and quality control measures that ensure their reliability and performance.

II. Raw Materials

A. Composition of Glass Glaze

The foundation of glass glaze resistors lies in their raw materials. The primary component is silica, which provides the glassy structure. Silica is often combined with various fluxing agents, such as sodium carbonate or potassium oxide, to lower the melting point and enhance the flow of the glaze during the firing process. Additionally, colorants and additives are incorporated to achieve specific aesthetic qualities and improve the glaze's performance characteristics.

B. Conductive Materials

In addition to the glass components, conductive materials are essential for the functionality of glass glaze resistors. Metal oxides, such as tin oxide or indium oxide, are commonly used to impart the necessary electrical properties. Carbon compounds may also be added to enhance conductivity and adjust the resistance values. The careful selection and proportioning of these materials are critical to achieving the desired electrical performance.

III. Preparation of Glass Glaze

A. Mixing Raw Materials

The first step in preparing the glass glaze involves mixing the raw materials in precise proportions. This process is crucial, as the ratios of silica, fluxing agents, and additives directly influence the final properties of the glaze. Homogenization techniques, such as ball milling or high-shear mixing, are employed to ensure a uniform mixture, which is essential for consistent quality in the final product.

B. Melting Process

Once the raw materials are thoroughly mixed, they undergo a melting process. This involves heating the mixture to high temperatures, typically between 1,200°C and 1,500°C, depending on the specific formulation. Temperature control is vital during this stage, as it affects the viscosity and flow characteristics of the glaze. The duration of melting is also carefully monitored to ensure complete fusion of the materials.

C. Cooling and Solidification

After melting, the glass glaze must be cooled and solidified. Controlled cooling techniques are employed to prevent the formation of defects, such as bubbles or cracks. The cooling process allows the molten glass to transition into a solid state, forming a stable and durable glaze that will serve as the foundation for the resistor.

IV. Fabrication of Resistors

A. Substrate Preparation

The next phase in the production of glass glaze resistors is the preparation of the substrate. Various types of substrates can be used, including ceramic, glass, or metal. Each substrate type has its advantages, such as thermal stability or electrical insulation properties. Surface treatment is often applied to enhance adhesion between the substrate and the glass glaze, ensuring a strong bond during the application process.

B. Application of Glass Glaze

There are several methods for applying the glass glaze to the substrate. The screen printing method is one of the most common techniques, where a stencil is used to transfer the glaze onto the substrate in precise patterns. Dip coating is another method, where the substrate is immersed in a glaze solution, allowing for uniform coverage. Other application techniques, such as spray coating or brush application, may also be employed depending on the desired outcome.

C. Shaping and Cutting

Once the glass glaze has been applied, the resistors must be shaped and cut to the desired dimensions. Techniques for shaping resistors can include stamping, laser cutting, or mechanical cutting. The goal is to achieve the specific size and form required for the intended application while maintaining the integrity of the glaze.

V. Firing Process

A. Purpose of Firing

Firing is a critical step in the production of glass glaze resistors. This process serves multiple purposes, including the curing of the glass glaze, the enhancement of electrical properties, and the stabilization of the resistor's structure. Firing also helps to eliminate any residual moisture from the glaze, ensuring optimal performance.

B. Firing Techniques

Kiln firing is the most common technique used in the production of glass glaze resistors. The resistors are placed in a kiln, where they are subjected to controlled heating according to specific temperature profiles. These profiles dictate the rate of temperature increase and the duration of firing, which can vary based on the composition of the glaze and the desired properties of the final product.

C. Effects of Firing on Resistor Properties

The firing process significantly impacts the properties of glass glaze resistors. Proper firing can enhance the electrical stability, thermal resistance, and mechanical strength of the resistors. Conversely, inadequate firing may lead to defects, such as poor adhesion or inconsistent resistance values, which can compromise the performance of the resistor in electronic circuits.

VI. Testing and Quality Control

A. Electrical Testing

Once the resistors have been fired, they undergo rigorous testing to ensure they meet the required specifications. Electrical testing involves measuring the resistance values and assessing the tolerance levels. This step is crucial, as it verifies that the resistors will perform reliably in their intended applications.

B. Physical Inspection

In addition to electrical testing, physical inspection is conducted to assess the overall quality of the resistors. Visual inspection is performed to identify any surface defects, such as cracks or bubbles, while mechanical testing evaluates the durability and strength of the resistors under stress.

C. Compliance with Standards

Compliance with industry standards is essential in the production of glass glaze resistors. Manufacturers must adhere to specific guidelines and certification processes to ensure their products meet safety and performance requirements. This commitment to quality helps build trust with customers and ensures the reliability of electronic components in various applications.

VII. Packaging and Distribution

A. Packaging Techniques

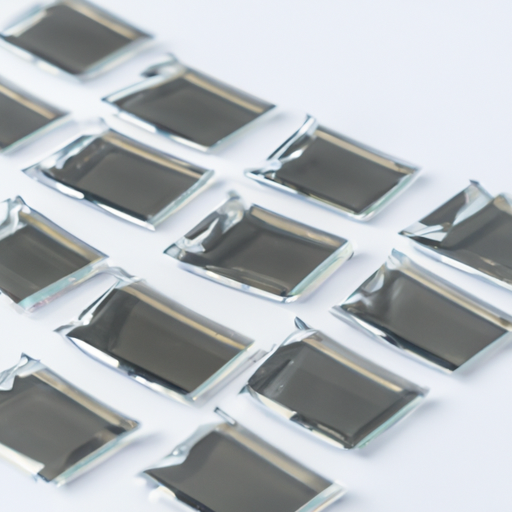

Once the resistors have passed all quality control measures, they are prepared for packaging. Protective packaging is essential to prevent damage during transportation and storage. Manufacturers often use anti-static materials and cushioning to safeguard the resistors from physical shocks and electrostatic discharge.

B. Distribution Channels

The distribution of glass glaze resistors can occur through various channels. Direct sales to manufacturers and electronic companies are common, as well as wholesale and retail distribution. Establishing strong relationships with distributors and customers is vital for ensuring a steady demand for these components.

VIII. Conclusion

The production process of mainstream glass glaze resistors is a complex and meticulous endeavor that involves multiple stages, from raw material selection to final testing and distribution. Each step is critical in ensuring the quality and reliability of these essential electronic components. As technology continues to evolve, manufacturers must embrace continuous improvement in production techniques to meet the growing demands of the electronics industry. Future trends may include advancements in materials science, automation in production processes, and enhanced quality control measures, all aimed at producing even more efficient and reliable glass glaze resistors.

IX. References

- Academic Journals on Materials Science and Electronics

- Industry Reports on Resistor Manufacturing

- Manufacturer Guidelines for Glass Glaze Resistors

This comprehensive overview of the production process of glass glaze resistors highlights the intricate steps involved in creating these vital components. Understanding this process not only sheds light on the importance of quality in electronic manufacturing but also emphasizes the ongoing innovations that drive the industry forward.