What are the Advantages of Non-Inductive Resistor Products?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling current flow and managing voltage levels. Among the various types of resistors available, non-inductive resistors stand out for their unique properties and advantages. This blog post will explore the definition of non-inductive resistors, their construction, and the key benefits they offer in various applications. By the end, you will have a comprehensive understanding of why non-inductive resistors are essential components in modern electronic circuits.

II. Understanding Non-Inductive Resistors

A. Explanation of Inductance in Resistors

Inductance is a property of electrical components that causes them to resist changes in current. In resistors, inductance can lead to unwanted effects, particularly in high-frequency applications. When current flows through a wire, it generates a magnetic field around it. If the wire is coiled or has a significant length, this magnetic field can induce a voltage that opposes the change in current, leading to inductive reactance. This phenomenon can distort signals and reduce the overall performance of electronic circuits.

B. How Non-Inductive Resistors are Constructed

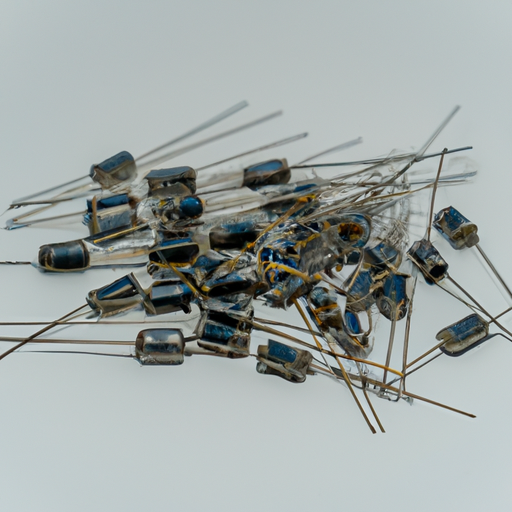

Non-inductive resistors are designed specifically to minimize or eliminate inductance. They are typically constructed using a flat wire or a thin film that is wound in a way that cancels out the magnetic fields generated by the current. This construction allows for a more uniform current distribution and significantly reduces the inductive effects that can occur in traditional resistors. The result is a component that maintains its performance even in high-frequency applications.

C. Comparison with Inductive Resistors

In contrast to non-inductive resistors, inductive resistors can introduce significant inductance into a circuit, which can lead to signal distortion and reduced efficiency. While inductive resistors may be suitable for low-frequency applications, they are often inadequate for high-speed or precision tasks. Non-inductive resistors, on the other hand, provide a more stable and reliable performance across a broader range of frequencies.

III. Key Advantages of Non-Inductive Resistor Products

A. Reduced Inductive Effects

1. Importance in High-Frequency Applications

One of the primary advantages of non-inductive resistors is their ability to minimize inductive effects. In high-frequency applications, such as RF (radio frequency) circuits, even small amounts of inductance can lead to significant signal degradation. Non-inductive resistors ensure that the integrity of the signal is maintained, allowing for clearer communication and more reliable performance.

2. Impact on Signal Integrity

Signal integrity is critical in many electronic applications, particularly in data transmission and communication systems. Non-inductive resistors help maintain the quality of the signal by reducing distortion and ensuring that the waveform remains intact. This is especially important in applications where precision and accuracy are paramount.

B. Improved Performance in Precision Applications

1. Stability and Accuracy

Non-inductive resistors are known for their stability and accuracy, making them ideal for precision applications. In measurement and calibration systems, even the slightest variation in resistance can lead to significant errors. Non-inductive resistors provide consistent performance, ensuring that measurements are reliable and accurate.

2. Applications in Measurement and Calibration

In test and measurement equipment, non-inductive resistors are often used to create reference standards. Their low inductance and high stability make them suitable for applications where precise resistance values are required. This is particularly important in laboratory settings and industrial applications where accuracy is critical.

C. Enhanced Thermal Stability

1. Heat Dissipation Characteristics

Non-inductive resistors are designed to handle heat more effectively than their inductive counterparts. They typically have better heat dissipation characteristics, which allows them to operate at higher power levels without overheating. This is particularly important in applications where resistors are subjected to continuous or high loads.

2. Reliability in Harsh Environments

In harsh environments, such as industrial settings or outdoor applications, components must be able to withstand extreme temperatures and conditions. Non-inductive resistors are often more reliable in these situations due to their enhanced thermal stability. They are less likely to fail or drift in value, ensuring consistent performance over time.

D. Lower Noise Generation

1. Importance in Audio and RF Applications

Noise generation is a critical concern in audio and RF applications. Inductive resistors can introduce unwanted noise into the signal, leading to distortion and reduced sound quality. Non-inductive resistors, with their minimal inductive effects, help to reduce noise generation, resulting in clearer audio and more reliable RF performance.

2. Impact on Overall System Performance

The overall performance of an electronic system can be significantly impacted by the quality of its components. By using non-inductive resistors, designers can ensure that their systems operate more efficiently and with greater fidelity. This is particularly important in high-end audio equipment and sensitive RF circuits.

E. Versatility in Design

1. Range of Available Values and Configurations

Non-inductive resistors come in a wide range of values and configurations, making them versatile components for various applications. Whether you need a high-power resistor for a power supply or a low-value resistor for a signal path, there is likely a non-inductive option available to meet your needs.

2. Compatibility with Various Circuit Designs

Non-inductive resistors can be easily integrated into different circuit designs, making them a popular choice among engineers and designers. Their compatibility with various configurations allows for greater flexibility in circuit design, enabling the creation of more efficient and effective electronic systems.

IV. Applications of Non-Inductive Resistors

A. Use in Audio Equipment

In audio equipment, non-inductive resistors are often used in crossover networks, amplifiers, and equalizers. Their low noise generation and high stability make them ideal for maintaining sound quality and ensuring accurate signal reproduction.

B. Role in RF and Microwave Circuits

Non-inductive resistors are essential in RF and microwave circuits, where signal integrity is critical. They are used in attenuators, matching networks, and other components to ensure that signals remain clear and undistorted.

C. Applications in Test and Measurement Equipment

In test and measurement equipment, non-inductive resistors are used to create reference standards and calibration tools. Their accuracy and stability make them indispensable in laboratory settings and industrial applications.

D. Importance in Power Electronics

In power electronics, non-inductive resistors are used in various applications, including snubber circuits, load resistors, and current sensing. Their ability to handle high power levels and maintain performance under stress makes them valuable components in these systems.

V. Considerations When Choosing Non-Inductive Resistors

A. Factors Influencing Selection

When selecting non-inductive resistors, several factors should be considered:

1. Power Rating

The power rating of a resistor indicates how much power it can handle without overheating. It is essential to choose a resistor with an appropriate power rating for your application to ensure reliability and performance.

2. Tolerance Levels

Tolerance levels indicate how much the actual resistance value may vary from the specified value. For precision applications, it is crucial to select non-inductive resistors with low tolerance levels to ensure accuracy.

3. Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. Selecting a resistor with a low temperature coefficient is important for applications where temperature fluctuations may occur.

B. Cost vs. Performance Trade-offs

While non-inductive resistors offer numerous advantages, they may come at a higher cost compared to traditional inductive resistors. It is essential to weigh the benefits of performance and reliability against the cost when making a selection.

C. Manufacturer Reputation and Quality Assurance

Choosing a reputable manufacturer is crucial when selecting non-inductive resistors. Quality assurance and testing processes can significantly impact the performance and reliability of the components.

VI. Conclusion

In summary, non-inductive resistors offer a range of advantages that make them essential components in modern electronics. Their ability to reduce inductive effects, improve performance in precision applications, enhance thermal stability, lower noise generation, and provide versatility in design makes them invaluable in various applications. As technology continues to evolve, the importance of non-inductive resistors will only grow, paving the way for more efficient and reliable electronic systems.

VII. References

- Citing relevant literature and studies on non-inductive resistors and their applications.

- Additional resources for further reading on resistor technology and advancements in electronic components.

By understanding the advantages of non-inductive resistors, engineers and designers can make informed decisions that enhance the performance and reliability of their electronic systems.