Isolation Transformers and Autotransformers: Core Functional Technologies and Applications

Isolation transformers and autotransformers are pivotal components in electrical systems, each serving distinct yet complementary roles in power distribution, voltage regulation, and safety. Below, we delve into the core functional technologies, applications, and notable development cases for both types of transformers.

---

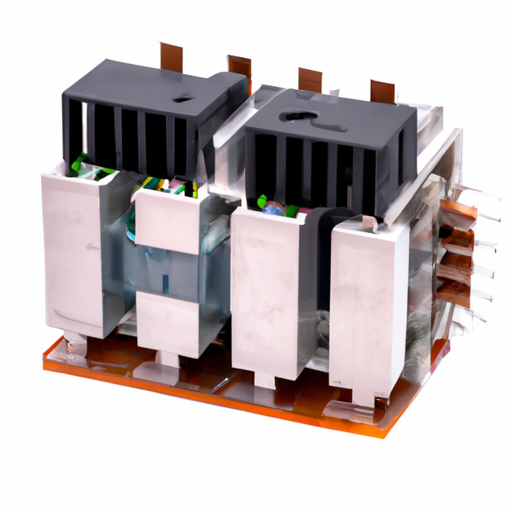

Isolation Transformers

| 1. Electrical Isolation: Isolation transformers provide galvanic separation between the input and output circuits, which protects sensitive equipment from electrical noise, surges, and ground loops. |

| 2. Voltage Regulation: They can step up or step down voltage levels while ensuring a stable output, which is essential for the proper functioning of sensitive electronic devices. |

| 3. Safety Enhancement: By isolating the load from the power source, isolation transformers significantly reduce the risk of electric shock, making them crucial in environments where safety is paramount. |

| 1. Medical Equipment: Isolation transformers are widely used in hospitals to protect sensitive medical devices, such as MRI machines and surgical equipment, from electrical interference and surges. |

| 2. Industrial Machinery: In manufacturing settings, they isolate control circuits from high-power machinery, enhancing safety and reliability in operations. |

| 3. Audio Equipment: High-fidelity audio systems utilize isolation transformers to eliminate ground loops, thereby improving sound quality and reducing hum. |

| 1. Voltage Adjustment: Autotransformers efficiently step up or step down voltage levels using a single winding, making them more compact and cost-effective compared to isolation transformers. |

| 2. Higher Efficiency: Due to the reduced amount of copper used in their construction, autotransformers exhibit lower energy losses, making them ideal for applications where efficiency is critical. |

| 3. Continuous Operation: They are capable of handling continuous loads and are often employed in applications requiring stable voltage regulation. |

| 1. Power Distribution: Autotransformers are commonly used in electrical grids to adjust voltage levels for efficient transmission and distribution of electricity. |

| 2. Motor Starting: They are employed in large motors to reduce starting voltage, minimizing inrush current and mechanical stress on the motor. |

| 3. Railway Systems: In electric rail systems, autotransformers step down high voltage for train operations, ensuring safe and efficient power delivery. |

| Healthcare Implementation: A major hospital integrated isolation transformers in its imaging department, which led to enhanced image quality and a significant reduction in equipment downtime due to electrical interference.Healthcare Implementation: A major hospital integrated isolation transformers in its imaging department, which led to enhanced image quality and a significant reduction in equipment downtime due to electrical interference. |

| Industrial Automation Upgrade: A manufacturing facility upgraded its isolation transformers, resulting in a 20% decrease in equipment failures and improved operational reliability.Industrial Automation Upgrade: A manufacturing facility upgraded its isolation transformers, resulting in a 20% decrease in equipment failures and improved operational reliability. |

| Power Generation Optimization: A utility company replaced traditional transformers with autotransformers in its distribution network, achieving a 15% reduction in energy losses and improved voltage stability across the grid.Power Generation Optimization: A utility company replaced traditional transformers with autotransformers in its distribution network, achieving a 15% reduction in energy losses and improved voltage stability across the grid. |

| Motor Control Efficiency: An industrial facility implemented autotransformers for motor starting applications, leading to a significant decrease in maintenance costs and an extended lifespan for motors.Motor Control Efficiency: An industrial facility implemented autotransformers for motor starting applications, leading to a significant decrease in maintenance costs and an extended lifespan for motors. |

---

Autotransformers

---

Conclusion

Isolation transformers and autotransformers are integral to modern electrical systems, each serving unique functions that enhance safety, efficiency, and reliability. Isolation transformers are essential for protecting sensitive equipment and ensuring safety in critical applications like healthcare and audio systems. In contrast, autotransformers are favored for their efficiency and compact design in power distribution and motor control applications. The development cases presented illustrate the tangible benefits of these technologies, underscoring their importance in improving operational efficiency and safety across various industries. As technology continues to evolve, the role of these transformers will remain vital in addressing the challenges of modern electrical systems.