The Current Situation of the Capacitor Brand Industry

I. Introduction

Capacitors are essential components in electronic devices, serving as energy storage units that help regulate voltage and power flow. They play a critical role in various applications, from consumer electronics to automotive systems, making the capacitor brand industry a vital segment of the global electronics market. This article aims to provide an overview of the current state of the capacitor brand industry, exploring market trends, major players, technological advancements, challenges, and future outlook.

II. Overview of the Capacitor Market

A. Market Size and Growth Trends

The global capacitor market has witnessed significant growth in recent years, driven by the increasing demand for electronic devices and advancements in technology. As of 2023, the market is valued at approximately $25 billion, with projections indicating a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is fueled by the rising adoption of capacitors in various sectors, including consumer electronics, automotive, and renewable energy.

B. Key Applications of Capacitors

Capacitors find applications across a wide range of industries:

1. **Consumer Electronics**: Capacitors are integral to devices such as smartphones, laptops, and televisions, where they help manage power supply and improve performance.

2. **Automotive Industry**: With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), capacitors are increasingly used for energy storage and power management.

3. **Industrial Applications**: Capacitors are employed in machinery and equipment for power factor correction and energy efficiency.

4. **Renewable Energy Systems**: Capacitors play a crucial role in solar inverters and wind turbines, helping to stabilize power output and improve efficiency.

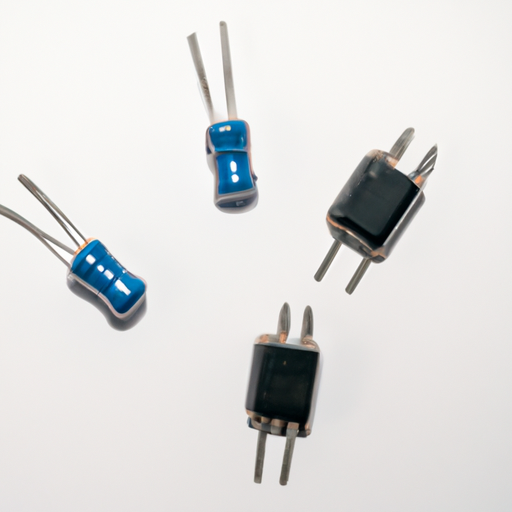

C. Types of Capacitors

The capacitor market comprises various types, each with unique characteristics and applications:

1. **Ceramic Capacitors**: Known for their small size and reliability, ceramic capacitors are widely used in consumer electronics.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values and are commonly found in power supply circuits.

3. **Film Capacitors**: Valued for their stability and low loss, film capacitors are used in audio equipment and industrial applications.

4. **Tantalum Capacitors**: Known for their high capacitance-to-volume ratio, tantalum capacitors are used in compact electronic devices.

III. Major Players in the Capacitor Brand Industry

A. Overview of Leading Capacitor Manufacturers

The capacitor brand industry is dominated by several key players:

1. **Murata Manufacturing Co., Ltd.**: A leading manufacturer known for its innovative ceramic capacitors and extensive product range.

2. **Nichicon Corporation**: Specializes in electrolytic capacitors and has a strong presence in the automotive and industrial sectors.

3. **KEMET Corporation**: Offers a diverse portfolio of capacitors, including tantalum and film capacitors, and is recognized for its commitment to sustainability.

4. **Vishay Intertechnology, Inc.**: A major player in the capacitor market, Vishay provides a wide range of products for various applications.

5. **Panasonic Corporation**: Known for its high-quality capacitors, Panasonic is a significant supplier to the consumer electronics and automotive industries.

B. Market Share Analysis

The competitive landscape of the capacitor brand industry is characterized by a few dominant players holding substantial market shares. Murata and Nichicon lead the market, followed closely by KEMET and Vishay. These companies invest heavily in research and development to maintain their competitive edge and meet the evolving demands of the market.

C. Competitive Strategies Employed by Major Brands

To stay competitive, major capacitor brands employ various strategies, including:

Innovation: Continuous investment in R&D to develop advanced capacitor technologies that meet the needs of emerging applications.

Sustainability: Focusing on eco-friendly manufacturing processes and products to address environmental concerns.

Strategic Partnerships: Collaborating with other technology firms to enhance product offerings and expand market reach.

IV. Technological Advancements

A. Innovations in Capacitor Technology

The capacitor industry is witnessing rapid technological advancements, including:

1. **Development of High-Capacitance and High-Voltage Capacitors**: These innovations enable capacitors to handle more power in smaller packages, catering to the demands of modern electronics.

2. **Advancements in Materials Used for Capacitors**: New materials, such as organic dielectrics and nanomaterials, are being explored to improve performance and reliability.

B. Impact of Technology on Product Performance and Reliability

Technological advancements have significantly enhanced the performance and reliability of capacitors. Improved materials and manufacturing processes result in capacitors that can withstand higher temperatures, voltages, and frequencies, making them suitable for a broader range of applications.

C. Role of Research and Development in Shaping the Future of the Industry

R&D plays a crucial role in the capacitor brand industry, driving innovation and enabling companies to stay ahead of the competition. As the demand for more efficient and compact electronic devices grows, manufacturers are investing in R&D to develop next-generation capacitors that meet these requirements.

V. Challenges Facing the Capacitor Brand Industry

A. Supply Chain Disruptions

The capacitor industry has faced significant challenges due to supply chain disruptions, particularly during the COVID-19 pandemic. These disruptions have led to shortages of raw materials and components, affecting production schedules and delivery times.

1. **Impact of Global Events**: Events such as the pandemic and geopolitical tensions have highlighted the vulnerabilities in global supply chains.

2. **Semiconductor Shortages**: The ongoing semiconductor shortage has also impacted the capacitor market, as many electronic devices rely on both components.

B. Environmental Regulations and Sustainability Concerns

As environmental regulations become more stringent, capacitor manufacturers are under pressure to develop eco-friendly products. This includes:

1. **Pressure to Develop Eco-Friendly Capacitors**: Companies are exploring alternatives to traditional materials and manufacturing processes to reduce their environmental impact.

2. **Recycling and Disposal Challenges**: The disposal of capacitors, particularly those containing hazardous materials, poses challenges that manufacturers must address.

C. Competition from Alternative Technologies

The rise of alternative energy storage technologies, such as supercapacitors, presents a challenge to traditional capacitor brands. Supercapacitors offer advantages in terms of energy density and charge/discharge cycles, leading to increased competition in the market.

VI. Future Outlook for the Capacitor Brand Industry

A. Predictions for Market Growth and Trends

The capacitor market is expected to continue its growth trajectory, driven by the increasing demand for electronic devices and advancements in technology. Key trends include the growing adoption of electric vehicles, the expansion of renewable energy systems, and the rise of smart technologies.

B. Potential Areas for Innovation and Development

Future innovations in the capacitor industry may focus on:

Higher Energy Density: Developing capacitors that can store more energy in smaller packages.

Smart Capacitors: Integrating sensors and communication capabilities into capacitors for enhanced functionality.

C. Strategic Recommendations for Capacitor Brands to Remain Competitive

To remain competitive in the evolving market, capacitor brands should consider:

Investing in R&D: Continuously innovate to meet the changing demands of the market.

Emphasizing Sustainability: Develop eco-friendly products and practices to align with regulatory requirements and consumer preferences.

Exploring New Markets: Identify and target emerging markets, such as electric vehicles and renewable energy, to expand their customer base.

VII. Conclusion

In summary, the capacitor brand industry is a dynamic and essential component of the global electronics market. With significant growth potential, driven by technological advancements and increasing demand across various sectors, the industry faces challenges that require adaptability and innovation. As manufacturers navigate supply chain disruptions and environmental concerns, the future of the capacitor brand industry will depend on their ability to innovate and respond to market demands.

VIII. References

- Market research reports on the capacitor industry

- Company profiles of leading capacitor manufacturers

- Articles on technological advancements in capacitor technology

- Environmental regulations and sustainability practices in the electronics industry

This overview provides a comprehensive understanding of the current situation of the capacitor brand industry, highlighting its importance and the factors influencing its future.