What are the Advantages of Capacitor Capacity Products?

I. Introduction

Capacitors are fundamental components in electrical engineering, serving a variety of roles in circuits and systems. The term "capacitor capacity products" refers to the various types of capacitors available, each with different capacitance values and characteristics. Understanding these products is crucial for engineers and designers who aim to optimize performance in electronic devices and systems. This article will explore the advantages of both high and low capacitor capacity products, their versatility, reliability, and environmental considerations, ultimately highlighting their importance in modern applications.

II. Understanding Capacitor Capacity

A. Explanation of Capacitance and Its Measurement

Capacitance is the ability of a capacitor to store electrical energy in an electric field, measured in Farads (F). A higher capacitance indicates a greater ability to store charge. Capacitors are essential in various applications, from power supply stabilization to signal processing.

B. Types of Capacitors and Their Applications

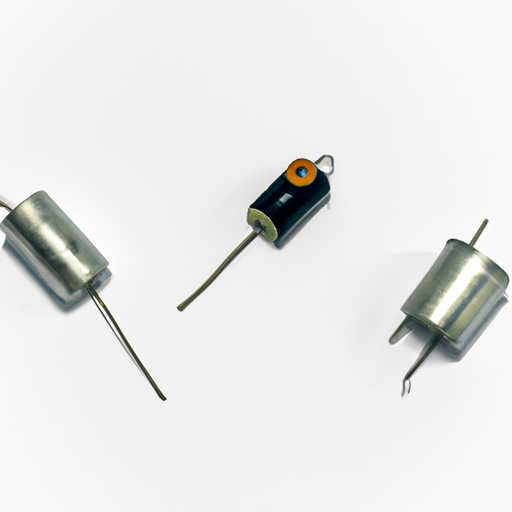

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are often used in power supply circuits and energy storage applications.

2. **Ceramic Capacitors**: These are widely used in high-frequency applications due to their stability and low losses. They are common in decoupling and filtering applications.

3. **Film Capacitors**: Known for their reliability and low self-inductance, film capacitors are used in audio equipment and power electronics.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small package, making them ideal for compact electronic devices.

C. Factors Influencing Capacitor Capacity

Several factors influence the capacity of a capacitor, including the dielectric material, the surface area of the plates, and the distance between them. Understanding these factors helps engineers select the right capacitor for specific applications.

III. Advantages of High Capacitor Capacity Products

A. Enhanced Energy Storage

High-capacity capacitors are essential in power supply systems, where they store energy and release it when needed. They play a crucial role in renewable energy systems, such as solar and wind, by smoothing out fluctuations in energy generation.

B. Improved Performance in Electronic Circuits

High-capacity capacitors help smooth voltage fluctuations in power supplies, ensuring stable operation of electronic devices. They are also used in filtering applications to remove noise from signals, enhancing overall circuit performance.

C. Increased Efficiency in Power Factor Correction

Power factor refers to the efficiency with which electrical power is converted into useful work output. High-capacity capacitors are used in industrial applications to correct power factor, reducing energy losses and improving system efficiency.

IV. Advantages of Low Capacitor Capacity Products

A. Compact Size and Lightweight Design

Low-capacity capacitors are often smaller and lighter, making them ideal for portable devices such as smartphones and laptops. Their compact design allows for more efficient use of space in consumer electronics.

B. Faster Response Times

Low-capacity capacitors have faster response times, making them suitable for high-frequency applications. They are commonly used in timing circuits and oscillators, where quick charge and discharge cycles are essential.

C. Cost-Effectiveness

Low-capacity capacitors are generally more affordable than their high-capacity counterparts. This cost-effectiveness benefits manufacturers and consumers alike, making them a popular choice in budget-sensitive applications.

V. Versatility and Customization

A. Range of Capacitor Capacity Products Available

The market offers a wide range of capacitor capacity products, from standard options to custom-designed capacitors tailored for specific applications. This versatility allows engineers to select the best capacitor for their needs.

B. Multi-functional Capacitors

Some capacitors come with integrated features, such as resistors or inductors, providing additional functionality in a single package. These multi-functional capacitors can simplify circuit design and save space, making them valuable in modern electronics.

VI. Reliability and Longevity

A. Durability of Capacitor Capacity Products

The lifespan of a capacitor is influenced by factors such as temperature, voltage, and the quality of materials used. High-quality capacitors are designed to withstand harsh conditions, ensuring durability and reliability in various applications.

B. Reduced Maintenance Costs

Investing in reliable capacitor capacity products can lead to long-term savings for industries. Fewer failures mean reduced maintenance costs and improved operational efficiency, making high-quality capacitors a wise choice for businesses.

VII. Environmental Considerations

A. Eco-friendly Capacitor Options

With growing environmental concerns, manufacturers are developing eco-friendly capacitor options. These include capacitors made from biodegradable materials and designs that promote energy efficiency, contributing to a more sustainable future.

B. Role in Sustainable Technology

Capacitors play a vital role in sustainable technology, particularly in renewable energy systems and electric vehicles. Their ability to store and release energy efficiently is crucial for the advancement of green energy solutions.

VIII. Conclusion

In summary, capacitor capacity products offer a range of advantages that are essential for modern electronic applications. High-capacity capacitors enhance energy storage and improve circuit performance, while low-capacity options provide compact designs and cost-effectiveness. The versatility and reliability of these products make them indispensable in various industries, from consumer electronics to renewable energy systems. As technology continues to evolve, the importance of capacitor capacity products will only grow, paving the way for innovative solutions in the future.

IX. References

1. "Capacitors: Principles and Applications" - Journal of Electrical Engineering

2. "The Role of Capacitors in Power Factor Correction" - IEEE Transactions on Power Electronics

3. "Eco-friendly Capacitors: A Sustainable Approach" - Environmental Science & Technology

4. "Advancements in Capacitor Technology" - Electronics Weekly

For further reading on capacitors and their applications, consider exploring the resources mentioned above. Understanding the advantages of capacitor capacity products is crucial for anyone involved in electrical engineering and electronics design.