What is the Current Status of the Porcelain Tube Resistor Industry?

I. Introduction

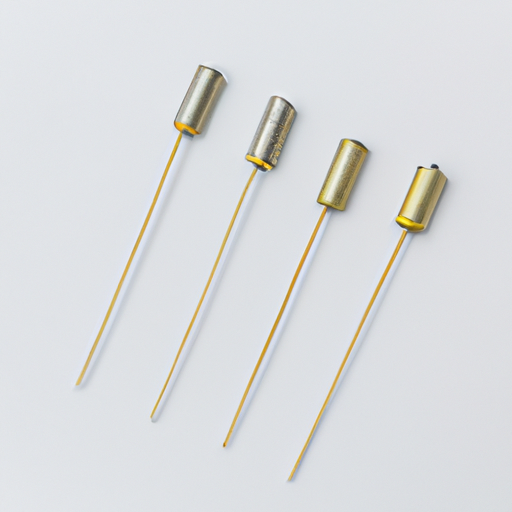

Porcelain tube resistors are essential components in various electronic applications, known for their durability, thermal stability, and reliability. These resistors, typically made from a combination of porcelain and resistive materials, play a crucial role in managing electrical currents and ensuring the safe operation of electronic devices. As industries evolve and technology advances, understanding the current status of the porcelain tube resistor industry is vital for stakeholders, manufacturers, and consumers alike. This article aims to provide a comprehensive overview of the porcelain tube resistor industry, exploring its historical context, current market dynamics, technological advancements, applications, challenges, and future outlook.

II. Historical Context

A. Development of Porcelain Tube Resistors

The journey of porcelain tube resistors began in the early 20th century, when the need for reliable electrical components surged alongside the growth of the electrical and electronics industries. Early innovations focused on creating resistors that could withstand high temperatures and harsh environments, leading to the development of porcelain as a primary material due to its excellent insulating properties.

B. Key Milestones in the Industry

Over the decades, the porcelain tube resistor industry has witnessed significant technological advancements. The introduction of automated manufacturing processes in the late 20th century improved production efficiency and consistency. Additionally, the growing demand for electronic devices and the expansion of industries such as telecommunications and automotive have driven market growth, establishing porcelain tube resistors as a staple in modern electronics.

III. Current Market Overview

A. Global Market Size and Growth Trends

As of 2023, the global porcelain tube resistor market is valued at approximately $1.2 billion, with a projected compound annual growth rate (CAGR) of 5% over the next five years. This growth is fueled by the increasing demand for electronic devices and the expansion of renewable energy systems.

B. Major Players in the Porcelain Tube Resistor Industry

The porcelain tube resistor market is characterized by a mix of established manufacturers and emerging companies. Key players include Vishay Intertechnology, Ohmite Manufacturing Company, and TE Connectivity, which collectively hold a significant market share. Additionally, several startups are entering the market, focusing on innovative designs and sustainable practices.

C. Market Segmentation

The market can be segmented by application and type. Key applications include automotive, industrial, and consumer electronics, with the automotive sector being the largest consumer of porcelain tube resistors. In terms of type, the market is divided into fixed, variable, and specialty resistors, each serving specific needs within various industries.

IV. Technological Advancements

A. Innovations in Manufacturing Processes

Recent innovations in manufacturing processes have significantly enhanced the production of porcelain tube resistors. Automation has streamlined operations, reducing labor costs and increasing output. Furthermore, advancements in materials science have led to the development of new composites that improve the performance and longevity of these resistors.

B. Advances in Design and Performance

The design of porcelain tube resistors has also evolved, with a focus on enhancing thermal stability and durability. Modern resistors are now capable of withstanding extreme temperatures and environmental conditions, making them suitable for a wider range of applications. Additionally, miniaturization trends in electronics have prompted manufacturers to develop smaller, more integrated resistor designs that can fit into compact electronic devices.

V. Applications and Demand Drivers

A. Key Industries Utilizing Porcelain Tube Resistors

Porcelain tube resistors find applications across various industries. The automotive industry relies on these resistors for electronic control units, power management systems, and safety features. In telecommunications, they are used in signal processing and transmission equipment. The renewable energy sector, particularly in solar and wind energy systems, also utilizes porcelain tube resistors for efficient energy management.

B. Factors Driving Demand

Several factors are driving the demand for porcelain tube resistors. The increasing usage of electronic devices, coupled with the growth of renewable energy and electric vehicles, has created a robust market for these components. Additionally, regulatory standards and safety requirements in various industries necessitate the use of reliable and durable resistors, further propelling demand.

VI. Challenges Facing the Industry

A. Supply Chain Issues

Despite the positive market outlook, the porcelain tube resistor industry faces several challenges. Supply chain disruptions, particularly in raw material availability and pricing, have impacted production capabilities. Global events, such as pandemics and geopolitical tensions, have exacerbated these issues, leading to increased costs and delays.

B. Competition from Alternative Technologies

The industry also faces competition from alternative resistor technologies, such as wirewound and film resistors. These alternatives often offer advantages in specific applications, leading to potential market share erosion for porcelain tube resistors. Manufacturers must continuously innovate to maintain their competitive edge.

C. Environmental Concerns

Environmental sustainability is becoming increasingly important in the manufacturing sector. The porcelain tube resistor industry must address concerns regarding the sustainability of materials used in production and comply with regulatory pressures for eco-friendly products. This shift towards sustainability presents both challenges and opportunities for manufacturers.

VII. Future Outlook

A. Predictions for Market Growth and Trends

Looking ahead, the porcelain tube resistor market is expected to continue its growth trajectory, driven by technological advancements and increasing demand from key industries. Innovations in materials and manufacturing processes will likely enhance the performance and application range of these resistors, opening new markets and opportunities.

B. Strategic Recommendations for Industry Players

To thrive in this evolving landscape, industry players should focus on several strategic initiatives. Investment in research and development is crucial to drive innovation and improve product offerings. Additionally, a commitment to sustainability and eco-friendly practices will resonate with consumers and regulatory bodies alike. Collaboration and partnerships with other companies can also foster innovation and expand market reach.

VIII. Conclusion

In summary, the porcelain tube resistor industry is at a pivotal point, characterized by growth opportunities and challenges. The historical context of these components highlights their importance in modern electronics, while current market dynamics reveal a robust demand driven by various industries. Technological advancements continue to shape the future of porcelain tube resistors, but industry players must navigate challenges such as supply chain issues and competition from alternative technologies. By adapting to market changes and focusing on innovation and sustainability, the porcelain tube resistor industry can look forward to a promising future.

IX. References

1. Vishay Intertechnology. (2023). Annual Report.

2. Ohmite Manufacturing Company. (2023). Product Catalog.

3. TE Connectivity. (2023). Market Analysis Report.

4. Industry Research Reports. (2023). Global Porcelain Tube Resistor Market Trends.

5. Journal of Electronic Materials. (2023). Innovations in Resistor Technology.

This blog post provides a detailed overview of the current status of the porcelain tube resistor industry, covering its historical context, market dynamics, technological advancements, applications, challenges, and future outlook. Each section is designed to inform and engage readers interested in understanding this critical component of modern electronics.