What are the Popular Automotive Resistor Product Types?

I. Introduction

In the world of automotive engineering, resistors play a crucial role in ensuring the proper functioning of various systems. These components are essential for managing electrical currents, regulating voltage, and conditioning signals within vehicles. This blog post aims to explore the different types of automotive resistors, their characteristics, applications, and the latest trends in resistor technology. By understanding these components, automotive professionals and enthusiasts can make informed decisions when selecting resistors for their applications.

II. Understanding Resistors in Automotive Applications

A. Basic Principles of Resistors

At its core, a resistor is a passive electrical component that opposes the flow of electric current. The relationship between voltage (V), current (I), and resistance (R) is defined by Ohm's Law, which states that V = I × R. This fundamental principle underpins the operation of resistors in various applications.

Resistors can be categorized into two main types: fixed and variable. Fixed resistors have a constant resistance value, while variable resistors allow for adjustments in resistance, making them versatile for different applications.

B. Role of Resistors in Automotive Systems

In automotive systems, resistors serve several critical functions:

1. **Current Regulation**: Resistors help control the amount of current flowing through circuits, protecting sensitive components from damage due to excessive current.

2. **Voltage Division**: Resistors can be used in voltage divider circuits to provide specific voltage levels required by various components, such as sensors and microcontrollers.

3. **Signal Conditioning**: Resistors are essential in filtering and conditioning signals, ensuring that the data received by electronic control units (ECUs) is accurate and reliable.

III. Common Types of Automotive Resistors

A. Fixed Resistors

Fixed resistors are the most commonly used type in automotive applications. They come in various materials and designs, each with unique characteristics.

1. Carbon Composition Resistors

**Characteristics**: Carbon composition resistors are made from a mixture of carbon and a binding material. They are known for their high energy absorption and ability to withstand high temperatures.

**Applications in Automotive**: These resistors are often used in applications where high pulse power is required, such as in ignition systems and power amplifiers.

2. Metal Film Resistors

**Characteristics**: Metal film resistors are constructed using a thin film of metal deposited on a ceramic substrate. They offer high precision, stability, and low noise.

**Applications in Automotive**: These resistors are commonly used in sensitive electronic circuits, such as those found in engine control units (ECUs) and sensor applications.

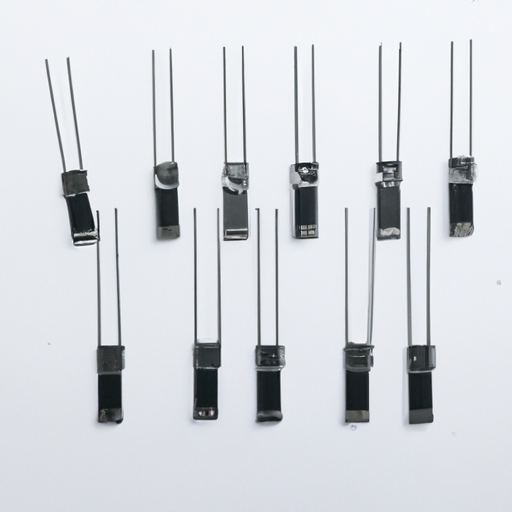

3. Wirewound Resistors

**Characteristics**: Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. They can handle high power levels and have excellent heat dissipation properties.

**Applications in Automotive**: These resistors are often used in applications requiring high power handling, such as in electric braking systems and motor control circuits.

B. Variable Resistors

Variable resistors allow for adjustments in resistance, making them suitable for applications where fine-tuning is necessary.

1. Potentiometers

**Characteristics**: Potentiometers consist of a resistive element and a movable contact (wiper). They can be adjusted to provide varying resistance levels.

**Applications in Automotive**: Potentiometers are commonly used in applications such as volume controls in audio systems, throttle position sensors, and climate control systems.

2. Rheostats

**Characteristics**: Rheostats are a type of variable resistor designed to handle higher currents. They typically have two terminals and are used to adjust current flow.

**Applications in Automotive**: Rheostats are often used in applications like dimming headlights and controlling fan speeds in heating and cooling systems.

C. Specialty Resistors

Specialty resistors are designed for specific applications, often involving unique characteristics.

1. Thermistors

**NTC and PTC Thermistors**: Thermistors are temperature-sensitive resistors that change resistance with temperature. NTC (Negative Temperature Coefficient) thermistors decrease resistance as temperature increases, while PTC (Positive Temperature Coefficient) thermistors increase resistance with rising temperature.

**Applications in Temperature Sensing**: Thermistors are widely used in automotive applications for temperature sensing, such as monitoring engine temperature, cabin temperature, and battery temperature.

2. Photoresistors

**Characteristics**: Photoresistors, or light-dependent resistors (LDRs), change resistance based on light exposure. They are made from semiconductor materials that exhibit photoconductivity.

**Applications in Light Sensing**: In automotive applications, photoresistors are used in automatic headlight systems and ambient light sensors to adjust interior lighting based on external light conditions.

3. Shunt Resistors

**Characteristics**: Shunt resistors are low-resistance resistors used to measure current. They are placed in series with a load, allowing for current measurement without significantly affecting the circuit.

**Applications in Current Measurement**: Shunt resistors are commonly used in battery management systems, electric vehicle applications, and monitoring systems to measure current flow accurately.

IV. Resistor Specifications and Ratings

When selecting resistors for automotive applications, several specifications and ratings must be considered:

A. Resistance Value and Tolerance

The resistance value is measured in ohms (Ω) and indicates how much the resistor opposes current flow. Tolerance refers to the allowable deviation from the specified resistance value, typically expressed as a percentage.

B. Power Rating

The power rating indicates the maximum power the resistor can dissipate without overheating. It is measured in watts (W) and is crucial for ensuring the resistor can handle the power levels in automotive applications.

C. Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. A lower temperature coefficient is desirable for automotive applications, as it ensures stable performance across varying temperature conditions.

D. Voltage Rating

The voltage rating specifies the maximum voltage the resistor can withstand without breaking down. It is essential to select resistors with appropriate voltage ratings to prevent failure in high-voltage automotive systems.

V. Trends and Innovations in Automotive Resistor Technology

As automotive technology continues to evolve, so do the resistors used in these applications. Some notable trends and innovations include:

A. Miniaturization and Integration

With the increasing demand for compact and lightweight automotive components, resistors are being designed to be smaller and more integrated into circuit boards. This trend allows for more efficient use of space and improved performance in modern vehicles.

B. Enhanced Thermal Management

As vehicles become more electrified, managing heat dissipation in resistors is becoming increasingly important. Innovations in materials and designs are being developed to enhance thermal management, ensuring resistors can operate effectively in high-temperature environments.

C. Smart Resistors and IoT Applications

The rise of the Internet of Things (IoT) is influencing the development of smart resistors that can communicate data about their performance and environmental conditions. These resistors can provide real-time feedback to automotive systems, improving efficiency and safety.

VI. Conclusion

In summary, automotive resistors are vital components that play a significant role in the functionality and reliability of modern vehicles. Understanding the different types of resistors, their characteristics, and applications is essential for automotive professionals and enthusiasts alike. As technology continues to advance, the future of automotive resistor technology looks promising, with innovations that will enhance performance, efficiency, and integration in automotive systems. When selecting the right resistor for automotive needs, it is crucial to consider specifications, ratings, and the specific application to ensure optimal performance and reliability.

VII. References

1. "Automotive Resistors: Types and Applications." Electronics Tutorials.

2. "Understanding Resistors: A Comprehensive Guide." All About Circuits.

3. "The Role of Resistors in Automotive Electronics." IEEE Xplore.

4. "Trends in Automotive Electronics: Resistor Technology." Automotive Engineering International.

This blog post provides a comprehensive overview of popular automotive resistor product types, their characteristics, applications, and the latest trends in the industry, serving as a valuable resource for anyone interested in automotive technology.