What are the Product Features of Resistor Manufacturers?

I. Introduction

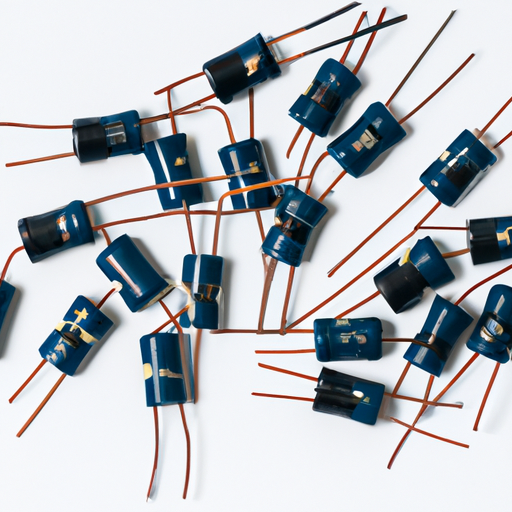

Resistors are fundamental components in electronic circuits, serving the critical function of controlling current flow. By providing resistance, they help to manage voltage levels, protect sensitive components, and ensure the proper functioning of electronic devices. Given their importance, the choice of resistor manufacturer can significantly impact the performance and reliability of electronic products. This blog post explores the various product features offered by resistor manufacturers, providing insights into the types of resistors available, key specifications, quality assurance practices, customization options, and current market trends.

II. Types of Resistors

Resistors come in various types, each designed for specific applications and performance requirements. Understanding these types is essential for selecting the right resistor for a given project.

A. Fixed Resistors

Fixed resistors maintain a constant resistance value. They are widely used in electronic circuits and can be categorized into several types:

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a higher tolerance and lower stability compared to other types.

2. **Metal Film Resistors**: These resistors are constructed using a thin film of metal, providing better stability and lower noise levels. They are favored in precision applications due to their tight tolerance levels.

3. **Wirewound Resistors**: Made by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in high-frequency applications.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits.

1. **Potentiometers**: Commonly used for volume control in audio equipment, potentiometers can vary resistance by adjusting a sliding contact along a resistive element.

2. **Rheostats**: Similar to potentiometers but designed to handle higher currents, rheostats are often used in applications requiring variable resistance, such as in lighting control.

C. Specialty Resistors

Specialty resistors are designed for specific applications and include:

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations, thermistors are widely used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure, making them ideal for light-sensing applications.

3. **Varistors**: Voltage-dependent resistors that protect circuits from voltage spikes, varistors are essential in surge protection applications.

III. Key Product Features of Resistor Manufacturers

When evaluating resistor manufacturers, several key product features should be considered to ensure optimal performance and reliability.

A. Resistance Value Range

1. **Standard Values**: Most manufacturers offer a range of standard resistance values, typically following the E12 or E24 series, which provide a set of preferred numbers for easy selection.

2. **Custom Values**: For specialized applications, many manufacturers provide custom resistance values, allowing designers to specify exact requirements.

B. Tolerance Levels

1. **Importance of Tolerance**: Tolerance indicates how much the actual resistance can vary from the stated value. It is crucial for applications requiring precision.

2. **Common Tolerance Ratings**: Resistors are available with various tolerance ratings, typically ranging from ±1% to ±20%, with tighter tolerances available for precision applications.

C. Power Rating

1. **Definition and Importance**: Power rating refers to the maximum power a resistor can dissipate without overheating. It is a critical specification for ensuring reliability in circuit design.

2. **Power Rating Options**: Manufacturers provide resistors with varying power ratings, from small signal resistors rated for milliwatts to high-power resistors capable of handling several watts.

D. Temperature Coefficient

1. **Explanation of Temperature Coefficient**: This specification indicates how much the resistance changes with temperature. A lower temperature coefficient is preferable for applications requiring stability across temperature variations.

2. **Impact on Performance**: Resistors with a low temperature coefficient are essential in precision applications, as they maintain consistent performance over a range of operating conditions.

E. Size and Form Factor

1. **Surface Mount vs. Through-Hole**: Resistors are available in surface mount (SMD) and through-hole configurations. SMD resistors are preferred for compact designs, while through-hole resistors are often used in prototyping and high-power applications.

2. **Miniaturization Trends**: As electronic devices become smaller, manufacturers are increasingly focusing on miniaturization, offering smaller form factors without compromising performance.

F. Material Composition

1. **Conductive Materials**: The choice of conductive materials, such as carbon, metal, or metal oxide, affects the resistor's performance characteristics, including stability and noise levels.

2. **Insulating Materials**: Insulating materials used in resistor construction also play a role in performance, particularly in high-voltage applications where dielectric strength is critical.

G. Environmental Ratings

1. **RoHS Compliance**: Many manufacturers adhere to the Restriction of Hazardous Substances (RoHS) directive, ensuring that their products are free from harmful substances.

2. **Operating Temperature Range**: Resistors are rated for specific operating temperature ranges, which is crucial for ensuring reliability in various environmental conditions.

3. **Moisture and Humidity Resistance**: Some resistors are designed to withstand high humidity and moisture levels, making them suitable for outdoor and harsh environments.

IV. Quality Assurance and Testing

Quality assurance is vital in resistor manufacturing to ensure reliability and performance.

A. Manufacturing Standards

1. **ISO Certifications**: Many reputable manufacturers hold ISO certifications, indicating adherence to international quality management standards.

2. **Industry Standards (e.g., IEC, JIS)**: Compliance with industry standards ensures that resistors meet specific performance and safety criteria.

B. Testing Procedures

1. **Electrical Testing**: Manufacturers conduct rigorous electrical testing to verify resistance values, tolerance, and power ratings.

2. **Environmental Testing**: Resistors undergo environmental testing to assess performance under various conditions, including temperature extremes and humidity.

3. **Reliability Testing**: Long-term reliability testing helps manufacturers ensure that their products will perform consistently over time.

V. Customization and Special Features

Customization options allow manufacturers to meet specific customer needs.

A. Custom Resistor Solutions

1. **Tailored Resistance Values**: Manufacturers can create resistors with custom resistance values to meet unique design requirements.

2. **Unique Form Factors**: Custom form factors can be developed for specific applications, ensuring compatibility with existing designs.

B. Value-Added Features

1. **Integrated Circuit Resistors**: Some manufacturers offer resistors integrated into circuits, reducing space and improving performance.

2. **Resistors with Built-in Protection**: Resistors with built-in protection features, such as fuses or diodes, provide additional safety in circuit designs.

C. Design Support and Consultation

Many manufacturers offer design support and consultation services, helping engineers select the right resistors for their applications and providing insights into best practices.

VI. Market Trends and Innovations

The resistor market is continually evolving, driven by technological advancements and changing consumer demands.

A. Advances in Resistor Technology

1. **Thin-Film and Thick-Film Technologies**: Innovations in thin-film and thick-film technologies have led to improved performance characteristics, including lower noise and higher stability.

2. **Smart Resistors**: The development of smart resistors, which can provide real-time data on performance and environmental conditions, is gaining traction in various applications.

B. Sustainability in Resistor Manufacturing

1. **Eco-friendly Materials**: Manufacturers are increasingly focusing on using eco-friendly materials in resistor production to minimize environmental impact.

2. **Energy-efficient Production Processes**: Sustainable manufacturing practices, including energy-efficient processes, are becoming a priority for many resistor manufacturers.

VII. Conclusion

In summary, the product features of resistor manufacturers encompass a wide range of specifications and options that are crucial for ensuring optimal performance in electronic circuits. From the types of resistors available to key specifications such as resistance value range, tolerance levels, and power ratings, understanding these features is essential for selecting the right components for any project. As technology continues to advance, the importance of choosing a reputable resistor manufacturer will only grow, ensuring that electronic devices remain reliable and efficient. The future of resistor technology and manufacturing looks promising, with ongoing innovations and a focus on sustainability paving the way for enhanced performance and environmental responsibility.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Websites and Product Catalogs

This blog post provides a comprehensive overview of the product features of resistor manufacturers, highlighting the importance of these components in electronic design and the factors to consider when selecting a manufacturer.