What is the Current Situation of the Heating Resistor Industry?

I. Introduction

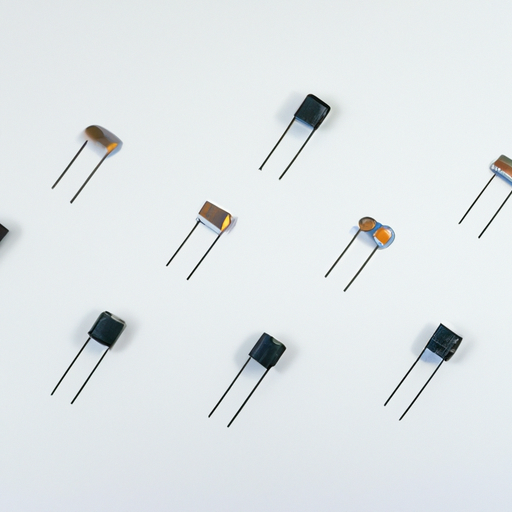

Heating resistors are essential components in various electrical and electronic systems, converting electrical energy into heat through resistive heating. They play a crucial role in applications ranging from industrial manufacturing processes to consumer electronics and medical devices. As the demand for efficient heating solutions continues to rise, the heating resistor industry is experiencing significant changes. This blog post explores the current state of the heating resistor industry, examining market trends, technological advancements, applications, regulatory considerations, challenges, and future outlook.

II. Market Overview

A. Global Market Size and Growth Trends

The global heating resistor market has witnessed substantial growth over the past few years. Historical data indicates a steady increase in demand, driven by the expansion of various sectors, including automotive, consumer electronics, and industrial manufacturing. As of 2023, the market is valued at approximately $XX billion, with projections suggesting a compound annual growth rate (CAGR) of XX% over the next five years. This growth is fueled by the increasing need for energy-efficient heating solutions and the rising adoption of smart technologies.

B. Key Players in the Heating Resistor Industry

The heating resistor industry is characterized by a mix of established manufacturers and emerging companies. Major players include [Company A], [Company B], and [Company C], which dominate the market with their extensive product portfolios and global reach. Emerging companies are also making their mark, focusing on innovative designs and sustainable practices. Market share analysis reveals that the top three players account for approximately XX% of the total market, while smaller companies are gaining traction by catering to niche markets and specialized applications.

III. Technological Advancements

A. Innovations in Heating Resistor Design

Recent advancements in heating resistor technology have led to significant improvements in design and materials. Manufacturers are increasingly utilizing materials such as ceramics and advanced metals to enhance performance and durability. Miniaturization has become a key trend, allowing for more compact designs that fit into smaller devices without compromising efficiency. These innovations not only improve the functionality of heating resistors but also contribute to overall energy savings.

B. Smart Heating Resistors and IoT Integration

The integration of smart technology into heating resistors is revolutionizing the industry. Smart heating resistors equipped with sensors and IoT capabilities offer enhanced control and monitoring, allowing users to optimize energy consumption. For instance, these devices can adjust their heating output based on real-time data, leading to significant energy savings. Applications of smart heating resistors are emerging in various sectors, including home automation, industrial processes, and automotive systems, showcasing their versatility and potential for widespread adoption.

IV. Applications of Heating Resistors

A. Industrial Applications

In industrial settings, heating resistors are integral to various manufacturing processes, including metal processing, plastic molding, and food production. They provide precise temperature control, ensuring product quality and consistency. The automotive industry also relies on heating resistors for applications such as engine heating and cabin temperature regulation, contributing to enhanced vehicle performance and comfort.

B. Consumer Electronics

Heating resistors are widely used in consumer electronics, particularly in home appliances like ovens, toasters, and hair dryers. Their ability to provide rapid and efficient heating makes them indispensable in these devices. Additionally, personal devices such as electric blankets and heated clothing are increasingly incorporating advanced heating resistors, catering to consumer demand for comfort and convenience.

C. Medical Applications

In the medical field, heating resistors play a vital role in various applications, including medical equipment and therapeutic devices. They are used in incubators, surgical instruments, and physical therapy devices, where precise temperature control is critical for patient safety and treatment efficacy. The growing emphasis on healthcare innovation is expected to drive further demand for specialized heating resistors in this sector.

V. Regulatory and Environmental Considerations

A. Industry Regulations and Standards

The heating resistor industry is subject to various regulations and standards aimed at ensuring safety and performance. Compliance with safety standards, such as IEC 60601 for medical devices and UL standards for consumer products, is essential for manufacturers. Additionally, environmental regulations are becoming increasingly stringent, pushing companies to adopt sustainable practices and materials in their production processes.

B. Sustainability Efforts

Sustainability is a growing concern in the heating resistor industry. Manufacturers are exploring eco-friendly materials and production methods to reduce their environmental impact. Initiatives focused on energy efficiency are also gaining traction, with companies investing in research and development to create products that consume less energy while maintaining performance. These efforts not only align with regulatory requirements but also resonate with environmentally conscious consumers.

VI. Challenges Facing the Industry

A. Supply Chain Disruptions

The heating resistor industry, like many others, has faced significant challenges due to supply chain disruptions caused by global events such as the COVID-19 pandemic and geopolitical tensions. These disruptions have led to shortages of raw materials and increased lead times, impacting production schedules and costs. Companies are now focusing on diversifying their supply chains and building resilience to mitigate future risks.

B. Competition from Alternative Technologies

Heating resistors face competition from alternative heating technologies, such as induction heating and infrared heating. These technologies offer distinct advantages, including faster heating times and improved energy efficiency. As a result, manufacturers of heating resistors must continuously innovate and enhance their products to remain competitive in a rapidly evolving market.

C. Cost Pressures

Rising raw material costs and manufacturing expenses pose significant challenges for the heating resistor industry. Fluctuations in the prices of metals and other materials can impact profit margins, forcing companies to find ways to optimize production processes and reduce costs. Additionally, the need for investment in research and development to keep pace with technological advancements adds further financial pressure.

VII. Future Outlook

A. Predictions for Market Growth

The future of the heating resistor industry appears promising, with continued growth expected in the coming years. As industries increasingly prioritize energy efficiency and sustainability, the demand for advanced heating solutions is likely to rise. Market analysts predict that the heating resistor market will reach a valuation of $XX billion by 2028, driven by innovations and expanding applications.

B. Emerging Trends to Watch

Several emerging trends are poised to shape the future of the heating resistor industry. The demand for energy-efficient solutions is expected to grow, with consumers and businesses alike seeking products that minimize energy consumption. Additionally, the integration of renewable energy sources into heating applications will create new opportunities for heating resistors, particularly in solar and wind energy systems.

C. Potential for Innovation and Research

The potential for innovation in the heating resistor industry is vast. Ongoing research into new materials, designs, and technologies will likely lead to the development of more efficient and versatile heating solutions. Collaboration between manufacturers, researchers, and technology developers will be crucial in driving these advancements and meeting the evolving needs of various industries.

VIII. Conclusion

In summary, the heating resistor industry is currently experiencing significant growth and transformation, driven by technological advancements, expanding applications, and increasing demand for energy-efficient solutions. While challenges such as supply chain disruptions and competition from alternative technologies persist, the industry's future outlook remains positive. As the importance of heating resistors continues to grow in the broader context of technology and energy, ongoing innovation and sustainability efforts will be key to ensuring the industry's success in the years to come. The heating resistor industry is not just a component of electrical systems; it is a vital player in the quest for efficient and sustainable energy solutions.