Chip Resistor Product Training Precautions

I. Introduction

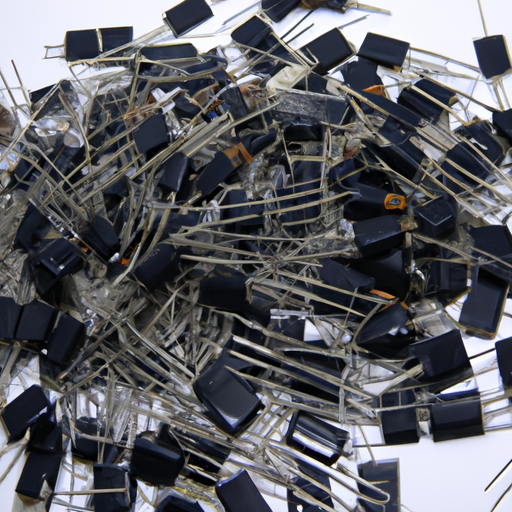

In the world of electronics, chip resistors play a crucial role in circuit design and functionality. These tiny components, often no larger than a grain of rice, are essential for controlling current flow and ensuring that electronic devices operate correctly. However, despite their small size, chip resistors require careful handling and proper training to ensure their effectiveness and reliability. This blog post will explore the importance of chip resistor training, the precautions necessary for their handling, and best practices for ensuring quality and safety in their use.

II. Understanding Chip Resistors

A. What are Chip Resistors?

Chip resistors are surface-mounted devices (SMDs) that provide resistance in electronic circuits. They come in various types, including thick film, thin film, and wire-wound resistors, each suited for different applications. Thick film resistors are commonly used for general-purpose applications, while thin film resistors offer higher precision and stability. Wire-wound resistors, on the other hand, are ideal for high-power applications.

B. Applications in Electronics

Chip resistors are found in a wide range of electronic devices, from smartphones and computers to automotive systems and medical equipment. Their compact size and reliability make them ideal for modern electronics, where space is often at a premium.

C. Key Specifications

Understanding the specifications of chip resistors is vital for their proper application. Key specifications include:

1. **Resistance Value**: Measured in ohms, this indicates how much the resistor opposes the flow of current.

2. **Tolerance**: This specification indicates the accuracy of the resistance value, typically expressed as a percentage.

3. **Power Rating**: Measured in watts, this indicates the maximum power the resistor can dissipate without failing.

4. **Temperature Coefficient**: This measures how much the resistance value changes with temperature, which is crucial for maintaining performance in varying environmental conditions.

III. Safety Precautions

A. Personal Protective Equipment (PPE)

When working with chip resistors, it is essential to prioritize safety. Personal protective equipment (PPE) should include:

1. **Gloves**: To prevent contamination and protect against sharp edges.

2. **Safety Glasses**: To shield the eyes from potential hazards during soldering or assembly.

3. **ESD (Electrostatic Discharge) Protection**: ESD can damage sensitive electronic components, so using wrist straps and ESD-safe work surfaces is crucial.

B. Work Environment

Creating a safe and organized work environment is essential for handling chip resistors. Key considerations include:

1. **Cleanliness and Organization**: A clutter-free workspace reduces the risk of accidents and contamination.

2. **Proper Ventilation**: Adequate airflow is necessary, especially when soldering, to avoid inhaling harmful fumes.

3. **Temperature and Humidity Control**: Maintaining optimal conditions helps prevent damage to sensitive components.

IV. Handling Chip Resistors

A. Proper Handling Techniques

To ensure the longevity and functionality of chip resistors, proper handling techniques must be employed:

1. **Avoiding Physical Damage**: Handle resistors gently to prevent cracking or breaking.

2. **Using Appropriate Tools**: Use tweezers or vacuum pick-up tools designed for SMDs to avoid direct contact.

B. Storage Guidelines

Proper storage is crucial for maintaining the integrity of chip resistors:

1. **Recommended Conditions**: Store resistors in a cool, dry place, away from direct sunlight and extreme temperatures.

2. **Avoiding Contamination**: Keep resistors in anti-static bags or containers to prevent contamination from dust and moisture.

C. Transportation Precautions

When transporting chip resistors, follow these precautions:

1. **Packaging Requirements**: Use anti-static packaging to protect resistors from ESD during transit.

2. **Handling During Transit**: Ensure that packages are secured to prevent movement and potential damage.

V. Soldering and Assembly Precautions

A. Soldering Techniques

Soldering is a critical process in assembling circuits with chip resistors. Recommended techniques include:

1. **Recommended Soldering Methods**: Use reflow soldering or hand soldering with appropriate soldering irons designed for SMDs.

2. **Temperature Control**: Monitor soldering temperatures to avoid overheating, which can damage the resistor.

B. Avoiding Common Soldering Mistakes

Common mistakes during soldering can lead to component failure:

1. **Overheating**: Prolonged exposure to high temperatures can damage the resistor's internal structure.

2. **Insufficient Solder**: Ensure that there is enough solder to create a reliable electrical connection.

C. Inspection After Soldering

After soldering, it is essential to inspect the work:

1. **Visual Inspection**: Check for proper alignment and solder joints.

2. **Testing for Functionality**: Use a multimeter to verify that the resistor is functioning within its specified parameters.

VI. Testing and Quality Assurance

A. Importance of Testing Chip Resistors

Testing is vital to ensure that chip resistors meet performance standards and specifications. Regular testing helps identify faulty components before they are integrated into larger systems.

B. Testing Methods

Several methods can be employed to test chip resistors:

1. **Multimeter Testing**: A simple and effective way to measure resistance values and check for continuity.

2. **Automated Testing Equipment**: For larger production runs, automated systems can quickly and accurately test multiple components.

C. Quality Control Measures

Implementing quality control measures is essential for maintaining high standards:

1. **Batch Testing**: Regularly test batches of resistors to ensure consistency and reliability.

2. **Compliance with Standards**: Adhere to industry standards and guidelines to ensure product quality.

VII. Troubleshooting Common Issues

A. Identifying Faulty Chip Resistors

Recognizing the symptoms of faulty chip resistors is crucial for effective troubleshooting:

1. **Symptoms of Failure**: Common signs include overheating, incorrect resistance values, or complete failure to conduct.

2. **Diagnostic Techniques**: Use multimeters and visual inspections to diagnose issues.

B. Solutions and Remediation

When issues are identified, prompt action is necessary:

1. **Replacement Procedures**: Follow proper procedures for removing and replacing faulty resistors.

2. **Preventative Measures**: Implement best practices to prevent future issues, such as regular training and adherence to handling guidelines.

VIII. Conclusion

In conclusion, chip resistors are vital components in modern electronics, and proper training in their handling is essential for ensuring their reliability and performance. By following the precautions outlined in this blog post, individuals and organizations can minimize risks and enhance the quality of their electronic products. Ongoing training and education are crucial for staying updated on best practices and industry standards. By fostering a culture of safety and quality, we can ensure that chip resistors continue to play a critical role in the advancement of technology.

IX. References

For further reading and to deepen your understanding of chip resistors, consider exploring the following resources:

1. **Suggested Reading Materials**: Books and articles on electronic components and circuit design.

2. **Industry Standards and Guidelines**: Documents from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

3. **Manufacturer Specifications and Datasheets**: Consult datasheets from reputable manufacturers for detailed information on specific chip resistor models.

By adhering to these guidelines and continuously improving our knowledge, we can ensure the effective use of chip resistors in our electronic designs.